AI for Tenant Satisfaction Surveys

Predictive maintenance is transforming industrial operations by moving from reactive repairs to proactive, preventative measures. This shift is driven by the ability to anticipate equipment failures before they occur, minimizing downtime and maximizing operational efficiency. By leveraging data analytics and machine learning, predictive maintenance empowers businesses to optimize maintenance schedules, reduce costs, and enhance safety. This approach allows for a more strategic and informed approach to maintenance, moving away from reactive fire-fighting and toward a more preventative and proactive strategy.

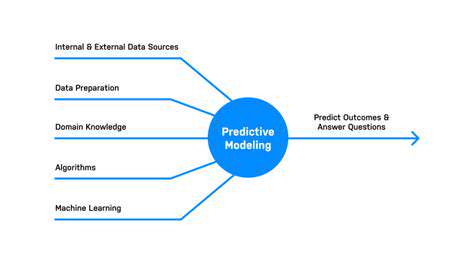

The fundamental principle behind predictive maintenance is the collection and analysis of data from various sources. This data, encompassing sensor readings, operational parameters, and historical maintenance records, is then used to develop predictive models that forecast potential equipment failures. This data-driven approach allows for proactive intervention, preventing costly breakdowns and ensuring continuous operation.

Key Benefits of Predictive Maintenance

The advantages of implementing predictive maintenance strategies extend beyond the obvious reduction in downtime. Predictive maintenance leads to significant cost savings by minimizing unscheduled repairs, reducing spare parts inventory, and optimizing maintenance schedules. This results in a significant return on investment (ROI) for businesses.

Predictive maintenance also enhances operational efficiency by optimizing production cycles and minimizing disruptions. Improved safety is another key benefit, as potential hazards are identified and addressed before they escalate into serious incidents. This ultimately leads to a more reliable and sustainable operational environment.

Data Collection and Analysis in Predictive Maintenance

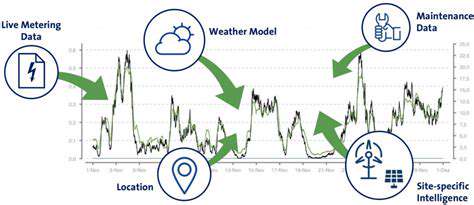

Accurate and reliable data collection is paramount to the success of any predictive maintenance program. This involves strategically placing sensors on critical equipment to capture real-time data on performance metrics, such as vibration, temperature, and pressure. The collected data is then processed and analyzed to identify patterns and anomalies that might indicate potential failures. Sophisticated algorithms and machine learning models are employed to analyze this data and generate predictive models.

Effective data analysis is crucial in identifying trends and anomalies. By analyzing past maintenance records, operational data, and sensor readings, predictive models can forecast potential equipment failures with a high degree of accuracy. This allows maintenance teams to intervene proactively, mitigating potential risks and maximizing operational uptime.

Implementation Strategies for Predictive Maintenance

Implementing a predictive maintenance program requires a phased approach. The initial phase involves evaluating existing systems and infrastructure to determine the best approach for data collection and analysis. Careful consideration of the specific needs and characteristics of the equipment being monitored is crucial for the successful implementation of predictive maintenance.

This includes establishing clear data collection protocols, identifying key performance indicators (KPIs), and deploying appropriate monitoring tools. Thorough training of personnel on the new procedures and technologies is also essential for the smooth transition and successful adoption of predictive maintenance strategies.

Future Trends in Predictive Maintenance

The future of predictive maintenance is poised for significant advancements, driven by innovations in sensor technology, data analytics, and machine learning. The development of more sophisticated sensors and IoT devices will enable the collection of more comprehensive and detailed data, leading to more accurate predictions. The increasing availability of powerful computing resources and sophisticated algorithms will also enhance the capabilities of predictive maintenance models, enabling faster and more accurate analysis of large datasets.

Furthermore, integration with other operational technologies, such as AI and robotics, will allow for the development of even more sophisticated maintenance strategies. This integrated approach will lead to even greater efficiencies and cost reductions in the future.

Improving Communication and Building Trust

Improving Communication

Effective communication is crucial for tenant satisfaction. AI-powered systems can analyze tenant feedback from surveys, identifying recurring themes and patterns that highlight areas for improvement in communication channels. This data-driven approach allows property managers to tailor their communication strategies to address specific concerns and needs, ultimately boosting tenant satisfaction and fostering a positive relationship. For example, AI can identify a high volume of negative feedback regarding delayed maintenance responses, prompting proactive communication and improved service delivery.

Proactive communication is key. AI can be programmed to send automated messages to tenants, providing updates on maintenance requests, upcoming events, or important notices. This proactive approach ensures tenants are informed and involved, reducing the potential for misunderstandings and fostering a sense of community within the building.

Building Trust Through Transparency

Transparency is essential to building trust between property managers and tenants. AI can analyze survey responses to pinpoint specific areas where tenants feel a lack of transparency. This data allows property managers to address these concerns directly, fostering a greater sense of trust and accountability. For example, if tenants frequently complain about a lack of information regarding building maintenance, AI can flag this concern and prompt the implementation of a more transparent communication strategy.

Personalized Feedback for Enhanced Satisfaction

AI-powered tools can analyze tenant survey data to identify specific needs and preferences for each individual tenant or group of tenants. This personalized feedback allows property managers to tailor their services and communication to meet individual expectations, leading to a more positive and fulfilling tenant experience. For instance, if a tenant frequently requests specific amenities, AI can identify this pattern and recommend the implementation of those amenities within the building.

Identifying and Addressing Pain Points

Tenant satisfaction surveys, when analyzed by AI, can reveal hidden pain points that might otherwise go unnoticed. By identifying recurring negative feedback, property managers can prioritize addressing these issues and implement solutions to enhance the overall tenant experience. For example, if multiple tenants complain about the quality of the building's landscaping, AI can flag this as a significant concern and prompt the implementation of improvements.

Proactive Problem Solving

AI can analyze survey data to predict potential tenant issues before they escalate. By identifying emerging trends and patterns in negative feedback, property managers can proactively address concerns, preventing issues from becoming major problems. This proactive approach not only boosts tenant satisfaction but also reduces operational costs associated with resolving significant issues.

Data-Driven Decision Making

AI-driven analysis of tenant satisfaction surveys provides valuable insights for data-driven decision-making. The insights derived from this analysis can guide property managers in making strategic decisions about resource allocation, service improvement, and overall building management. This data-driven approach allows property managers to optimize their operations and maximize tenant satisfaction.

Predictive Maintenance and Proactive Management

AI can analyze survey data and maintenance records to predict potential maintenance issues and schedule repairs proactively. This predictive maintenance approach reduces the likelihood of unexpected breakdowns and ensures that maintenance is addressed before it negatively impacts tenant satisfaction. By identifying patterns in maintenance requests and potential issues, AI can help property managers preemptively address problems and maintain the quality of the living environment.