Modular Construction for Affordable Housing

Modular Construction: Defining the Approach

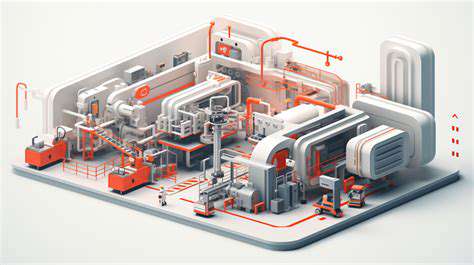

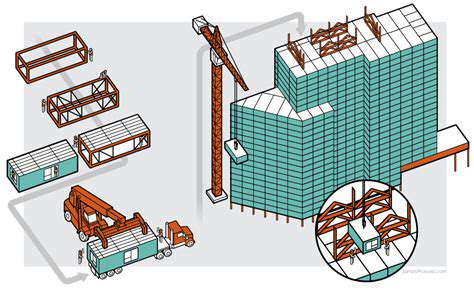

Modular construction is a rapidly evolving building method that involves prefabricating building components in a controlled factory environment. This approach contrasts with traditional on-site construction, where materials are assembled directly at the building location. The key advantage lies in the enhanced efficiency and precision achieved through off-site manufacturing. This allows for better quality control, reduced construction time, and potentially lower costs.

Key features of modular construction include the use of standardized modules, which are designed and manufactured to specific dimensions and specifications. This ensures precise fit and minimizes on-site adjustments. The prefabrication process also typically results in a significant reduction in construction waste and labor hours. This is especially important in projects with tight deadlines and complex designs.

Benefits of Modular Construction

One of the most significant advantages of modular construction is the potential for reduced construction time. By prefabricating components off-site, construction crews can focus on the assembly process, which can be significantly accelerated. This leads to faster project completion, enabling quicker occupancy and return on investment for clients.

Furthermore, modular construction often leads to improved quality control. The controlled environment of a factory allows for meticulous attention to detail and the use of advanced technologies, resulting in higher-quality components. This precision translates into fewer errors and defects during the assembly phase, ultimately leading to a more durable and reliable final product.

Design and Engineering Considerations

Modular construction requires a shift in design thinking, moving away from traditional site-specific designs towards designs that are readily adaptable to modular components. This often involves a collaborative approach between architects, engineers, and modular construction specialists. Careful consideration must be given to the integration of MEP (mechanical, electrical, and plumbing) systems within the modules, ensuring compatibility and efficiency.

Furthermore, the structural integrity of the modules must be meticulously designed and tested to ensure they can withstand the intended load requirements. This includes careful analysis of the load paths, connection points, and support systems. Careful planning during the design phase can minimize potential structural issues and ensure the long-term stability and safety of the constructed building.

Challenges and Considerations

One of the challenges in modular construction is the need for skilled labor in both the factory and the construction site. Training and development programs are crucial to ensure that workers possess the necessary expertise in handling and assembling the modules. This specialized knowledge is essential to ensure efficient and high-quality construction.

Another challenge is the efficient transportation and delivery of the prefabricated modules to the construction site. This requires careful planning and coordination to ensure timely delivery and minimize potential delays. Logistics must be carefully considered to avoid any disruptions to the construction schedule.

Streamlined Construction and Faster Turnaround Times

Modular Construction's Impact on Turnaround Times

Modular construction significantly reduces project timelines by prefabricating components in a controlled factory environment. This process minimizes on-site work, allowing for faster assembly and significantly accelerating the overall construction schedule. The pre-assembled modules are transported to the job site, ready for integration, eliminating delays often associated with traditional construction methods, such as material procurement and coordination issues.

The efficiency gains are particularly noticeable in large-scale projects, where the potential for streamlining the construction process and reducing delays is substantial. This translates into quicker project completion, which is a major benefit for developers, contractors, and end-users alike.

Prefabrication: A Key Driver of Efficiency

Prefabrication is at the heart of modular construction. By creating components off-site, modular construction minimizes the impact of weather delays and site constraints. This controlled environment allows for precise quality control, ensuring that components meet the highest standards and fit together seamlessly. This streamlined approach eliminates issues that can arise from on-site construction, such as weather-related delays, material shortages, and labor disputes.

Cost Savings Through Optimized Resource Allocation

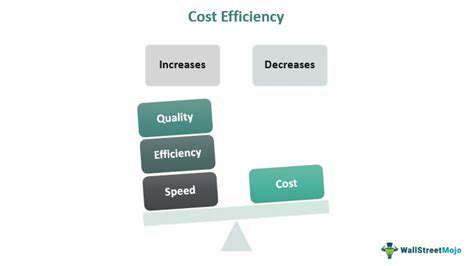

Modular construction often leads to substantial cost savings. By prefabricating components, materials are utilized more efficiently, minimizing waste and reducing material costs. The streamlined construction process also reduces labor costs by minimizing on-site labor hours and optimizing the use of specialized equipment. This meticulous approach to resource allocation is a key contributor to affordability in modular construction projects.

Reduced On-Site Labor Needs and Risks

Modular construction methods significantly reduce the need for extensive on-site labor. Pre-assembled modules require less time for on-site assembly, resulting in a smaller workforce needed at the construction site. This reduces labor-related risks, such as accidents and safety concerns. Furthermore, the controlled factory environment for prefabrication minimizes the complexities of managing a large workforce on a construction site, leading to a more predictable and controlled project.

Improved Quality Control and Precision

The controlled factory environment of modular construction allows for rigorous quality control measures to be implemented throughout the prefabrication process. This precision in manufacturing ensures that components meet the highest standards of quality and fit perfectly with other modules. This meticulous approach to quality control reduces the likelihood of errors and rework, leading to a higher overall quality of the finished product. The result is a more durable and long-lasting structure.

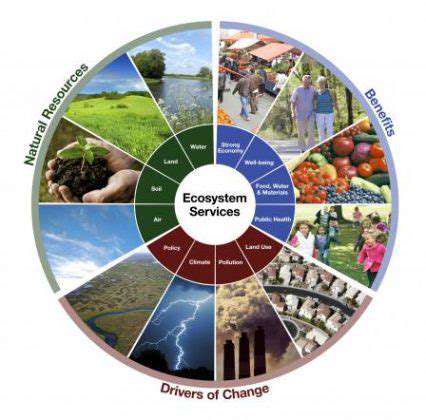

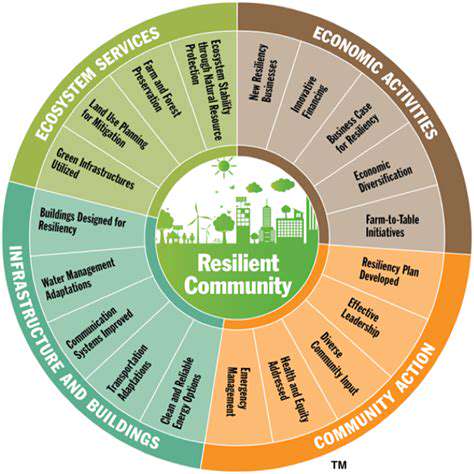

Sustainable Practices through Efficiency and Reduced Waste

Modular construction often incorporates sustainable practices. The prefabrication process allows for precise material use and minimizes waste, significantly reducing the environmental impact. The efficiency gains in construction timelines also contribute to a more sustainable project by reducing overall energy consumption and minimizing transportation needs for materials. These aspects make modular construction a more environmentally friendly option compared to traditional construction methods.

Sustainability and Quality Control: Further Benefits

Improved Efficiency and Reduced Waste

Modular construction inherently fosters efficiency through prefabrication. Components are manufactured off-site in controlled environments, minimizing on-site material handling and reducing the potential for errors and waste. This streamlined approach allows for more precise material utilization, leading to significant cost savings and a decreased environmental footprint. Prefabricated components also arrive on-site ready for assembly, which accelerates construction timelines and reduces the overall project duration. This leads to quicker project completion, saving time and money for the client, and minimizing potential delays due to unforeseen circumstances.

The precise nature of off-site fabrication often results in better material utilization. Detailed pre-planning and precise measurements minimize material waste during the construction process. By pre-cutting and pre-assembling components in a controlled environment, builders can more effectively use the available materials, minimizing the need for additional ordering or disposal of excess materials. This approach aligns directly with sustainable practices, promoting responsible resource management and reducing environmental impact.

Enhanced Quality Control and Safety

Modular construction allows for rigorous quality control measures to be implemented in a controlled factory environment. The controlled factory environment permits the use of advanced technology and specialized equipment, which result in greater precision and accuracy in the manufacturing process. This leads to more consistent and higher-quality components, ultimately contributing to a more durable and resilient final structure. The quality control measures implemented during the prefabrication stage significantly reduce the risk of defects and errors that often occur on-site during traditional construction.

Safety is another significant benefit of modular construction. By prefabricating components in a controlled factory environment, hazards associated with on-site construction are minimized. This includes the reduced risk of falls, equipment malfunctions, and exposure to harsh weather conditions. The prefabrication process allows for better planning and risk mitigation, leading to a safer work environment for construction workers and a greater overall safety record for the project.

Sustainable Practices and Material Selection

Modular construction provides an excellent opportunity to incorporate sustainable materials and practices throughout the entire process. The controlled factory environment allows for the selection and utilization of eco-friendly materials, such as recycled materials or those with low embodied energy. The prefabrication stage enables the use of specialized equipment and processes that can optimize the use of these materials, minimizing waste and maximizing their effectiveness. This focus on sustainable materials aligns perfectly with environmental conservation efforts, promoting a more responsible approach to construction.

Furthermore, the modular approach allows for greater transparency and traceability in the supply chain. Knowing the origin and quality of materials used in the construction process is crucial for ethical and sustainable practices. Modular construction facilitates this transparency, enabling builders to choose materials sourced from sustainable and ethical providers, contributing to a more responsible and environmentally conscious construction process.

Cost-Effectiveness and Time Savings

Modular construction often leads to significant cost savings through optimized material use and reduced on-site labor. By pre-assembling components in a controlled environment, the need for extensive on-site adjustments and labor is minimized. This streamlines the construction process, saving both time and money, while maintaining high standards of quality and safety. These cost savings are often passed on to the client, making modular construction a potentially more cost-effective option compared to traditional construction methods.

The prefabrication stage allows for better project planning and scheduling, leading to reduced project timelines. Components are manufactured and tested in advance, ensuring a smooth and efficient assembly process on-site. This accelerated construction schedule translates to quicker project completion, saving valuable time and potentially reducing overall project costs.

Read more about Modular Construction for Affordable Housing

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

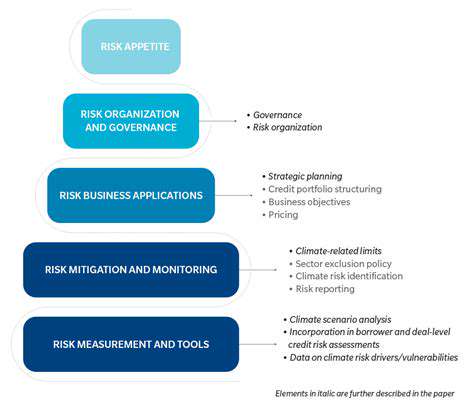

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing