AI in Property Management: Smart Repair Systems

Streamlined Repair Requests and Communication

Streamlined Processes for Repair Requests

Efficiently handling repair requests is crucial for maintaining operational excellence and minimizing downtime. A streamlined process allows for quicker identification of the issue, faster response times, and ultimately, a more satisfied customer base. By implementing a well-defined system, we can significantly reduce the time it takes to address repair needs, leading to greater productivity and profitability. This system should incorporate clear communication channels and standardized procedures to ensure accountability and transparency throughout the process.

Improved Communication and Collaboration

Effective communication is paramount for successful repair requests. Clear and concise communication between technicians, management, and clients is essential to ensure everyone is on the same page and working towards a shared goal. This is especially important when dealing with complex issues, ensuring that everyone understands the steps required to resolve the problem efficiently. Collaboration between different departments is critical to gather all necessary information and resources to reach a prompt and effective resolution.

Enhanced Tracking and Reporting

Implementing a robust tracking system for repair requests allows for better oversight and management of the entire process. This system should provide real-time updates on the progress of each request, keeping all stakeholders informed and up-to-date on the status. This transparency promotes accountability and helps in identifying bottlenecks or areas needing improvement within the system. Reports generated from this system provide valuable insights into trends and performance, allowing for data-driven decision-making and continuous improvement.

Prioritization and Resource Allocation

Repair requests often vary in urgency and complexity. A well-structured prioritization system is needed to ensure that the most critical requests are addressed promptly. This system should take into account factors like potential impact on operations, safety concerns, and customer satisfaction. Prioritization ensures that resources are allocated effectively, focusing on the most pressing needs first, and maximizing efficiency and productivity. This allocation process should be transparent and easily understood by all involved parties.

Customer Satisfaction and Feedback

Ultimately, the goal is to provide excellent service and maintain high customer satisfaction. A streamlined repair request process should focus on providing timely and accurate updates to customers. This includes keeping customers informed about the progress of their repair request and proactively addressing any concerns they may have. Collecting customer feedback is essential for continuous improvement, allowing us to identify areas for enhancement and refine our processes for future requests. This feedback loop is a critical element in maintaining a positive relationship with our clients.

Automated Inspection and Reporting

Automated Inspection Process

The automated inspection process utilizes advanced image processing algorithms to identify defects and anomalies in various products, materials, and structures. These algorithms are trained on vast datasets of high-quality images, enabling them to quickly and accurately detect subtle variations from expected standards. This process significantly reduces the time and resources required for manual inspection, allowing for faster turnaround times and increased efficiency.

The process typically involves capturing images of the target item, preprocessing these images to remove noise and enhance features, and then applying the trained algorithms to analyze the images. This automated approach offers the potential to improve consistency and accuracy compared to manual inspection methods, ultimately leading to higher product quality.

Data Acquisition and Preprocessing

A critical component of the automated inspection process is the acquisition of high-quality images or data. This requires careful consideration of lighting, camera resolution, and environmental factors to minimize distortions and ensure accurate representations of the target. The preprocessing stage is equally important, as it prepares the data for analysis by removing noise, enhancing features, and normalizing the image or data set. Proper preprocessing steps are crucial to the overall accuracy and effectiveness of the inspection system.

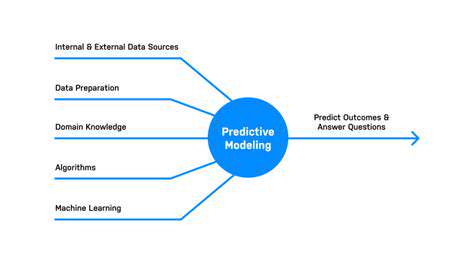

Defect Detection Algorithms

Sophisticated algorithms are employed to analyze the processed data and identify defects. These algorithms can detect a wide range of defects, from subtle variations in color or texture to more significant structural flaws. The development and refinement of these algorithms are key to achieving high accuracy and precision in the automated inspection process.

Different algorithms may be employed, depending on the nature of the products or materials being inspected. For instance, machine learning algorithms like convolutional neural networks (CNNs) are often used for image-based inspections, while other algorithms may be more suitable for analyzing sensor data from physical structures.

Reporting and Visualization

Once defects are detected, the system generates detailed reports summarizing the findings. These reports often include images highlighting the location and characteristics of the detected defects, along with quantitative metrics to assess the severity and extent of the issues. Clear and concise reporting is essential for efficient communication and decision-making.

Integration with Existing Systems

A key aspect of successful implementation is the seamless integration of the automated inspection system with existing manufacturing or quality control processes. This integration allows for real-time feedback and automated responses to detected defects, such as triggering corrective actions or flagging specific products for further review. This integration streamlines the workflow and enhances overall productivity.

Performance Evaluation and Optimization

The performance of the automated inspection system needs to be regularly evaluated and optimized to ensure ongoing accuracy and effectiveness. This involves analyzing the system's detection rates, false positive rates, and overall efficiency metrics to identify areas for improvement. Regular performance monitoring allows for continuous refinement of the algorithms and processes to maintain high quality standards.

Cost-Benefit Analysis

Implementing automated inspection systems can involve significant upfront costs, but the long-term benefits often outweigh the initial investment. The system's ability to reduce labor costs, improve product quality, and minimize defects translates into considerable savings over time. A comprehensive cost-benefit analysis is essential to justify the investment and demonstrate the return on investment (ROI) for the system.

Read more about AI in Property Management: Smart Repair Systems

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing