IoT Sensors for Predictive Maintenance in Buildings

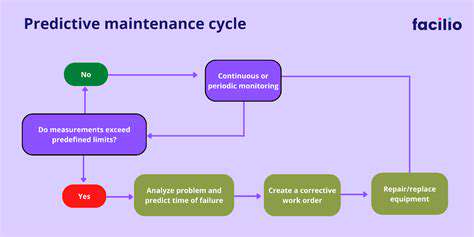

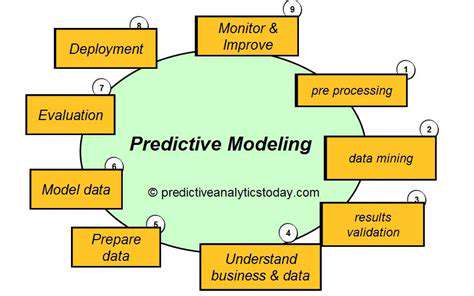

Predictive maintenance (PdM) is a proactive approach to equipment maintenance that aims to predict when equipment failures are likely to occur. Instead of relying on reactive maintenance, which addresses problems only after they happen, PdM utilizes data analysis and advanced technologies to anticipate potential issues and schedule maintenance before they cause significant downtime or costly repairs. This approach significantly reduces maintenance costs and improves overall equipment effectiveness.

The core principle of PdM is the analysis of equipment data to identify patterns and anomalies. This data can include sensor readings, operational data, and historical maintenance records. By analyzing these data sources, maintenance teams can identify potential failures before they manifest as complete equipment breakdowns, allowing for timely interventions.

Key Benefits of Predictive Maintenance

Implementing predictive maintenance offers a multitude of advantages for organizations across various industries. Reduced downtime is a primary benefit, as PdM allows for proactive maintenance interventions, minimizing the time equipment is out of service. This, in turn, leads to increased productivity and improved operational efficiency.

Predictive maintenance also helps to minimize the risk of costly equipment failures. By anticipating potential problems, organizations can schedule maintenance work during periods of low operational demand, potentially avoiding more expensive emergency repairs.

Data Collection and Analysis in PdM

A crucial aspect of predictive maintenance is the effective collection and analysis of relevant data. This involves deploying sensors on equipment to monitor various parameters such as vibration, temperature, pressure, and more. The data collected is then analyzed using sophisticated algorithms and machine learning techniques to identify patterns, anomalies, and potential failure points.

Accurate data analysis is paramount to the success of PdM. Inaccurate or incomplete data can lead to flawed predictions and ineffective maintenance strategies. Robust data collection protocols and thorough analysis are essential components of a successful PdM implementation.

Machine Learning and AI in Predictive Maintenance

Machine learning (ML) and artificial intelligence (AI) play a critical role in predictive maintenance. AI algorithms can be trained on historical data to identify complex patterns and relationships that may not be apparent to human analysts. This allows for more accurate predictions of equipment failures and enables more effective maintenance scheduling.

These advanced technologies enable PdM to predict failures with greater accuracy and precision than traditional methods. AI-driven models can learn from historical data, identify subtle trends, and anticipate potential failures well in advance, enabling proactive and cost-effective maintenance interventions.

The Role of Sensors in Data Collection

Sensors are essential tools in predictive maintenance, as they provide real-time data about equipment health and performance. Different types of sensors are used to collect various data points, such as vibration sensors for detecting unusual vibrations and temperature sensors for monitoring heat buildup.

Accurate sensor readings are critical for generating reliable predictive models. Regular calibration and maintenance of sensors are essential to ensure data accuracy and prevent false alarms or missed potential failures. Reliable sensor data forms the foundation for effective PdM implementation.

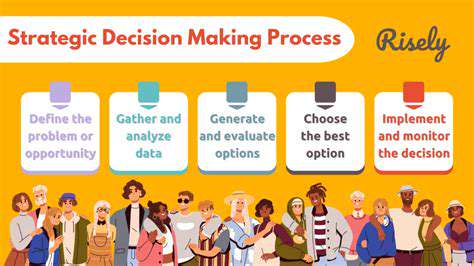

Implementing Predictive Maintenance Strategies

Successfully implementing a predictive maintenance strategy requires a comprehensive approach that considers various factors. This includes the selection of appropriate sensors, development of effective data analysis models, and integration with existing maintenance systems.

A critical aspect of successful PdM implementation is strong collaboration between maintenance teams, engineering personnel, and data scientists. Open communication and shared understanding of the data analysis process are vital for the effective use of predictive maintenance in improving overall equipment performance. Clear communication fosters a culture of proactive maintenance.

Future Trends in Predictive Maintenance

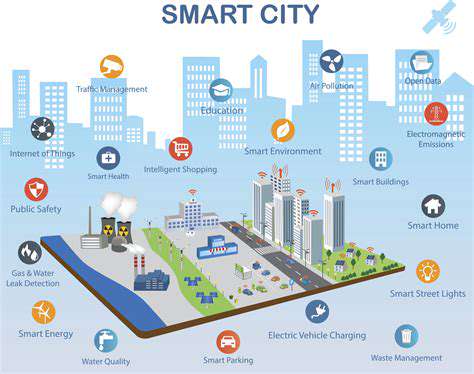

The field of predictive maintenance is constantly evolving, with new technologies and approaches emerging all the time. The integration of the Industrial Internet of Things (IIoT) is rapidly changing how data is collected and analyzed, allowing for more comprehensive and real-time insights into equipment performance.

The future of PdM likely involves even more sophisticated AI algorithms and advanced data analytics techniques. This will allow for more accurate predictions, leading to even greater cost savings and operational efficiency. PdM will likely continue to evolve, driven by the ongoing development of new technologies and the growing need for proactive and cost-effective maintenance solutions.

Key IoT Sensors for Building Predictive Maintenance

Temperature Sensors

Temperature sensors are crucial for monitoring the thermal conditions of equipment. They provide vital data for identifying potential issues like overheating, which can lead to component failure. By tracking temperature fluctuations over time, predictive maintenance systems can anticipate problems before they occur, enabling proactive maintenance schedules. This proactive approach minimizes downtime and maximizes equipment lifespan. Accurate temperature monitoring prevents costly breakdowns and ensures optimal performance.

Different types of temperature sensors exist, each with its specific range and accuracy. Thermocouples, resistance temperature detectors (RTDs), and integrated circuits (ICs) are commonly used in industrial settings. Choosing the right sensor type is crucial for reliable data collection, ensuring that the readings accurately reflect the true temperature of the equipment being monitored.

Vibration Sensors

Vibration sensors are essential for detecting unusual vibrations in machinery. These vibrations can indicate mechanical issues such as misalignment, looseness, or bearing wear. By continuously monitoring vibration levels, predictive maintenance systems can identify these problems before they escalate into major breakdowns. This early detection allows for timely interventions, minimizing costly repairs and preventing production disruptions.

Analyzing vibration data patterns helps identify potential anomalies. Sophisticated algorithms can distinguish between normal operating vibrations and abnormal patterns, triggering alerts for necessary maintenance actions. This proactive approach to maintenance significantly reduces unexpected downtime and improves overall equipment effectiveness.

Pressure Sensors

Pressure sensors are vital for monitoring the pressure levels within equipment. Changes in pressure can indicate leaks, blockages, or other internal issues. By tracking pressure fluctuations over time, predictive maintenance systems can identify potential problems early on. This allows for preventative measures to be taken, preventing catastrophic failures and costly repairs.

Different types of pressure sensors are available, each designed for specific pressure ranges. Choosing the appropriate sensor is crucial for accurate readings and reliable data. Monitoring pressure levels ensures optimal performance and prevents unexpected breakdowns, thereby maximizing equipment lifespan.

Humidity Sensors

Humidity sensors play a crucial role in monitoring environmental conditions that can impact equipment performance. High or low humidity levels can cause corrosion, condensation, or other issues that lead to equipment malfunctions. By detecting changes in humidity, predictive maintenance systems can proactively address these problems before they lead to major breakdowns. This allows for implementing preventative measures, ensuring equipment reliability and extending its lifespan.

Monitoring humidity levels is particularly important in environments with fluctuating humidity, such as industrial settings or outdoor installations. By identifying potential humidity-related issues early on, predictive maintenance systems can minimize equipment downtime and prevent costly repairs. This proactive approach to maintenance ensures optimal equipment performance.

Flow Sensors

Flow sensors are critical for monitoring the flow rate of liquids or gases through equipment. Changes in flow rate can indicate clogs, leaks, or other issues that can lead to reduced efficiency or equipment failure. By tracking flow rates over time, predictive maintenance systems can detect these problems early on, allowing for preventive maintenance actions to be taken before they result in major breakdowns.

Different types of flow sensors are available, each with specific capabilities and limitations. Choosing the appropriate sensor for the application is essential for accurate measurements and reliable data. Monitoring flow rates ensures that equipment operates within its optimal range and prevents unexpected issues that can lead to costly repairs and production downtime. By implementing predictive maintenance systems, organizations can optimize resource utilization and maintain operational efficiency.

Accurate flow monitoring is critical for many industrial processes. Precise measurements of fluid or gas flow rates are essential for maintaining production targets and preventing bottlenecks. Predictive maintenance systems can identify subtle changes in flow patterns that might indicate impending issues, providing proactive solutions to prevent costly breakdowns and disruptions. Regular monitoring and analysis of flow data are key to maximizing equipment uptime and ensuring optimal performance.

Future Trends and Applications in Building IoT

Emerging Technologies

The rapid advancement of artificial intelligence (AI) and machine learning (ML) is poised to revolutionize various sectors, including healthcare, finance, and transportation. These technologies are enabling the creation of intelligent systems that can automate complex tasks, analyze vast datasets, and make predictions with unprecedented accuracy. This will lead to significant improvements in efficiency and productivity across industries.

Furthermore, the integration of the Internet of Things (IoT) is creating interconnected networks of devices, enabling real-time data collection and analysis. This data-driven approach is transforming industries by providing insights into operational processes, enabling predictive maintenance, and optimizing resource allocation.

Enhanced User Experiences

User experience (UX) design is evolving at a rapid pace, driven by advancements in technology and user expectations. Intuitive interfaces, personalized experiences, and seamless integration across devices are becoming increasingly crucial for businesses to thrive in the modern digital landscape. The development of virtual reality (VR) and augmented reality (AR) technologies is further enhancing user engagement and interaction with digital products and services.

The focus on creating immersive and engaging experiences is evident in the rise of interactive storytelling, virtual exhibitions, and personalized learning platforms. This shift will continue to shape the design and development of products and services for the foreseeable future.

Personalized Learning and Education

Personalized learning platforms are transforming the educational landscape by tailoring learning experiences to individual student needs and preferences. This approach allows students to learn at their own pace and focus on areas where they need additional support. This approach fosters a more engaging and effective learning environment for all students.

Furthermore, advancements in online learning platforms and educational technologies are making education more accessible and affordable to a wider range of individuals. The integration of AI-powered tools can further refine personalized learning pathways, providing tailored feedback and adaptive learning experiences, resulting in more effective knowledge acquisition.

Sustainable Practices and Environmental Impact

The growing awareness of environmental issues is driving a shift towards sustainable practices across industries. The development of eco-friendly technologies and processes is becoming increasingly crucial for businesses to maintain a positive environmental footprint. This includes the use of renewable energy sources, the reduction of waste, and the implementation of sustainable supply chains.

Innovative solutions such as carbon capture and storage technologies, along with the development of more energy-efficient products and services, are critical for mitigating climate change and promoting environmental sustainability. This trend is expected to continue as regulatory pressure and consumer demand for sustainability increase.

Advancements in Healthcare and Wellness

The healthcare industry is experiencing significant advancements in areas like telemedicine, personalized medicine, and AI-powered diagnostics. These advancements are improving access to healthcare, reducing costs, and enhancing patient outcomes. The development of wearable health devices is also enabling individuals to monitor their health more effectively and proactively manage their well-being.

Furthermore, the use of AI in medical imaging and drug discovery is accelerating the pace of innovation in healthcare. This trend is expected to continue as technology advances and becomes more integrated into healthcare systems.