AI Powered Predictive Maintenance for Smarter Commercial Buildings

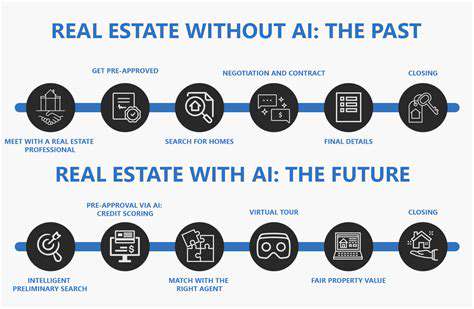

Intelligent building management systems are increasingly incorporating AI-powered predictive maintenance, marking a significant shift from reactive to proactive strategies. Instead of waiting for equipment failures to occur, these systems analyze data from various sources to anticipate potential issues and schedule maintenance before problems arise. This proactive approach minimizes downtime, reduces repair costs, and maximizes the lifespan of critical building systems.

This predictive approach is enabled by the sophisticated algorithms embedded within these systems. These algorithms learn from historical data, current operational parameters, and external factors like weather patterns to identify subtle indicators of impending failures. This allows for a more informed and strategic approach to maintenance, dramatically improving overall building efficiency.

Data-Driven Insights for Optimized Performance

The core of intelligent building management lies in the ability to collect, analyze, and act upon data. AI algorithms sift through vast amounts of data from sensors, building automation systems, and even external weather reports. This data encompasses everything from energy consumption patterns to equipment performance metrics, providing a comprehensive picture of the building's health and operational efficiency.

By identifying trends and anomalies, AI can pinpoint potential issues before they escalate. This data-driven approach allows building managers to optimize energy consumption, predict maintenance needs, and ultimately improve the overall performance and sustainability of the building.

Enhanced Energy Efficiency through AI

AI-powered intelligent building management systems are instrumental in achieving significant energy savings. By analyzing energy consumption patterns, the systems can identify areas where energy waste occurs and recommend adjustments to HVAC systems, lighting controls, and other energy-intensive components. This proactive approach to energy management contributes to a more sustainable and cost-effective building operation.

Furthermore, the system can adjust energy usage based on real-time conditions. For example, if a significant drop in temperature is predicted, the system can preemptively adjust heating settings, minimizing energy waste and maximizing comfort.

Improved Occupant Comfort and Wellbeing

Beyond energy efficiency, AI-powered systems contribute to a more comfortable and productive environment for occupants. By monitoring environmental conditions like temperature, humidity, and air quality, the system can automatically adjust settings to maintain optimal levels of comfort. This personalized approach enhances the overall occupant experience and can even contribute to improved employee productivity.

Reduced Operational Costs and Increased ROI

The long-term benefits of implementing AI-powered predictive maintenance are significant. By minimizing downtime, preventing costly repairs, and optimizing energy consumption, these systems generate a substantial return on investment. Reduced operational costs translate into significant financial savings for building owners and managers, making the investment in AI-powered intelligent building management systems a worthwhile endeavor.

The Future of Building Management: AI Integration

The future of building management is inextricably linked to the integration of AI. As AI technology continues to evolve, we can expect even more sophisticated and insightful predictive maintenance capabilities. This will lead to further advancements in energy efficiency, occupant comfort, and overall building performance. The intelligent building of the future will be a dynamic and responsive entity, optimized for efficiency, sustainability, and occupant well-being.

By embracing AI, building managers can unlock a new era of proactive building management, ensuring long-term operational success and sustainable practices.

Leveraging Data for Proactive Maintenance

Data-Driven Insights for Enhanced Performance

Analyzing historical data provides crucial insights into past trends and patterns, enabling proactive adjustments to maintain optimal performance. By identifying recurring issues or opportunities, businesses can anticipate potential challenges and implement preventative measures. This proactive approach is far more effective than reacting to problems after they arise, allowing for more efficient resource allocation and improved overall outcomes.

Understanding customer behavior through data analysis allows for the development of targeted strategies. This knowledge enables businesses to tailor products, services, and marketing campaigns to meet specific needs and preferences. This personalized approach leads to improved customer satisfaction, increased loyalty, and ultimately, higher profitability.

Predictive Modeling for Future Planning

Employing predictive modeling techniques allows businesses to forecast future trends and outcomes. By identifying potential risks and opportunities, organizations can develop strategies to mitigate negative impacts and capitalize on favorable situations. This forward-thinking approach empowers businesses to make informed decisions, minimizing uncertainty and maximizing potential returns.

Predictive modeling can be applied across various aspects of a business, from sales forecasting to inventory management. By accurately anticipating future demands, businesses can optimize resource allocation, reduce waste, and ensure smooth operations. This level of planning leads to improved efficiency and profitability.

Optimizing Resource Allocation Through Data Analysis

Data analysis offers invaluable insights into resource utilization patterns. Identifying areas of inefficiency and waste helps businesses optimize resource allocation, ensuring that resources are directed towards the most productive activities. This targeted approach leads to significant improvements in operational efficiency and cost savings.

By understanding which resources are most effective and where they are most needed, businesses can make strategic decisions to maximize output and minimize waste. This data-driven approach fosters a more streamlined and efficient organizational structure, ultimately leading to greater profitability.

Proactive Problem Solving Through Data Identification

Data analysis allows businesses to identify potential problems before they escalate into major crises. By monitoring key performance indicators and identifying emerging trends, proactive measures can be implemented to address potential issues. This preventative approach minimizes disruptions and maintains operational stability.

Proactive problem solving is crucial for maintaining a competitive edge in today's dynamic business environment. By anticipating and addressing issues before they impact operations, businesses can maintain a smooth workflow, avoid costly downtime, and maintain customer satisfaction. This level of preparedness is essential for long-term success in any market.

Predicting Failures and Optimizing Maintenance Schedules

Predictive Maintenance: A Paradigm Shift

Predictive maintenance, driven by AI, represents a significant shift from reactive to proactive maintenance strategies. Instead of waiting for equipment failures to occur, AI-powered systems analyze vast amounts of data to identify patterns and predict potential issues, enabling timely interventions and minimizing downtime. This proactive approach not only reduces costly repairs but also extends the lifespan of equipment and improves overall operational efficiency.

This new paradigm leverages the power of machine learning algorithms to analyze complex sensor data, operational logs, and historical maintenance records. By identifying subtle anomalies and trends that humans might miss, AI systems can pinpoint potential failures before they escalate, allowing for preventative measures to be implemented, safeguarding assets and preventing costly breakdowns.

Data Collection and Analysis: The Foundation of AI-Powered Prediction

Accurate predictions rely heavily on the quality and quantity of data. AI systems require access to real-time sensor data, operational parameters, and historical maintenance records. Robust data collection strategies, coupled with sophisticated data analysis techniques, are essential for developing reliable predictive models. This includes integrating various data sources, ensuring data consistency, and implementing robust data validation procedures to guarantee the accuracy of the insights derived from the data.

Furthermore, integrating data from disparate sources, like different machinery and departments within a facility, provides a more holistic view of the operational environment, allowing AI to identify hidden correlations and predict failures with greater precision. This comprehensive understanding of the operational context is crucial for effective maintenance planning.

Optimizing Maintenance Schedules with AI

AI-powered predictive maintenance systems can dynamically adjust maintenance schedules, optimizing them for maximum efficiency and cost-effectiveness. By accurately forecasting potential failures, these systems can prioritize maintenance tasks, ensuring that resources are allocated effectively and that critical equipment receives the necessary attention at the optimal time. This enables companies to avoid unnecessary maintenance interventions while ensuring critical equipment is maintained effectively.

Improving Operational Efficiency and Reducing Costs

Predictive maintenance significantly improves operational efficiency by minimizing downtime and maximizing equipment uptime. The ability to anticipate and prevent failures reduces the need for unscheduled repairs, saving valuable time and resources. Furthermore, the optimized maintenance schedules translate directly into cost savings by reducing the frequency of costly repairs and minimizing the use of expensive spare parts. This translates into a substantial return on investment (ROI) for organizations adopting AI-powered predictive maintenance.

The Future of Predictive Maintenance: Enhanced Capabilities and Integration

The future of predictive maintenance is characterized by enhanced capabilities and seamless integration with existing operational systems. AI systems will continue to evolve, incorporating more sophisticated algorithms and advanced analytics techniques, enabling more precise predictions and proactive interventions. Furthermore, integration with other technologies like IoT and cloud computing will enable real-time data analysis and seamless information sharing, maximizing the impact of predictive maintenance on various industrial applications.