Eco Friendly Building Materials: Performance and Cost

Exploring Specific Eco-Friendly Materials

Sustainable Materials in Construction

The construction industry is a significant contributor to environmental problems, largely due to the use of non-renewable resources and the generation of substantial waste. Shifting towards sustainable materials is crucial for mitigating these impacts. This involves exploring alternatives to traditional materials like concrete and steel, opting for recycled materials, and employing bio-based products. Implementing these changes can reduce the carbon footprint of construction projects and promote a circular economy, minimizing waste and maximizing resource efficiency.

Sustainable building materials are not just environmentally friendly, but also often more cost-effective in the long run, considering factors like reduced energy consumption and lower maintenance costs over the lifespan of a structure. This long-term financial benefit, coupled with the positive environmental impact, makes the transition to eco-friendly materials a compelling proposition for architects, builders, and homeowners alike.

Reducing Material Waste in Manufacturing

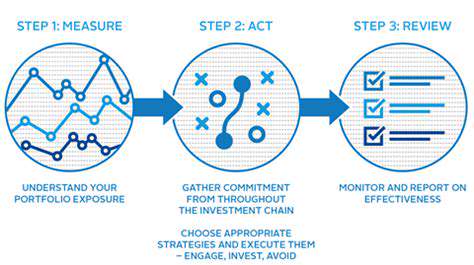

Minimizing waste throughout the manufacturing process is essential for eco-friendly production. Implementing strategies like optimized material usage, precise cutting techniques, and the reuse of scrap materials can significantly reduce the environmental footprint of manufacturing processes. This approach not only minimizes waste but also conserves natural resources and reduces the need for new raw materials, creating a more sustainable manufacturing cycle.

Adopting circular economy principles is paramount in reducing material waste. This involves designing products with disassembly and reuse in mind, ensuring materials can be recovered and repurposed at the end of their lifecycle. Companies that prioritize this approach are not only reducing their environmental impact but also gaining a competitive advantage by optimizing resource use and minimizing waste disposal costs.

Renewable Energy Integration

Integrating renewable energy sources into construction projects is a crucial step towards eco-friendly building practices. Utilizing solar panels, wind turbines, or geothermal systems can significantly reduce reliance on fossil fuels and lower the overall carbon footprint of buildings. These renewable energy systems provide a sustainable power source, contributing to a more eco-friendly and responsible approach to construction.

Optimizing the design of buildings to maximize energy efficiency is also essential. This includes incorporating passive design strategies, such as natural ventilation and daylighting, to reduce the need for artificial lighting and heating systems. These energy-efficient building designs not only reduce energy consumption but also create a healthier and more comfortable indoor environment for occupants.

Eco-Friendly Building Design Principles

Implementing eco-friendly building design principles is critical for creating sustainable structures. These principles encompass factors like site selection, material choices, energy efficiency, and waste management. Careful site selection can minimize environmental impact by preserving natural habitats and reducing the need for extensive land clearing.

Sustainable design choices often prioritize natural light and ventilation to reduce reliance on artificial lighting and heating systems. This not only lowers energy consumption but also creates a healthier and more comfortable indoor environment. Consideration of these principles during the design phase ensures a building's long-term environmental performance and reduces its overall carbon footprint.

Carbon Footprint Assessment and Mitigation

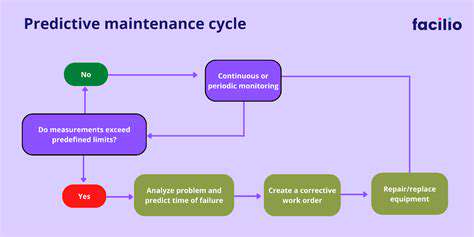

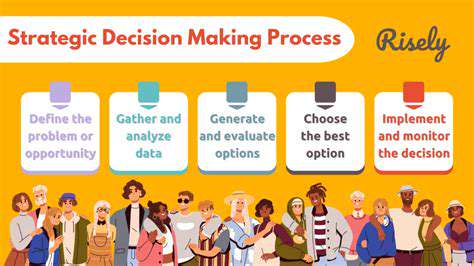

Assessing and mitigating the carbon footprint of construction projects is crucial for environmental responsibility. This involves evaluating the environmental impact of materials, construction methods, and energy consumption throughout the entire project lifecycle. Thorough assessments provide valuable data for informed decision-making and identify areas for improvement to reduce environmental impact.

Employing sustainable design strategies and implementing eco-friendly materials can significantly reduce the carbon footprint of a building. Careful planning and monitoring throughout the project can help identify and mitigate potential environmental risks, ensuring a more responsible and sustainable approach to construction projects.

Strategies for Minimizing Costs

Inventory Management Strategies

Effective inventory management is crucial for minimizing costs. Maintaining optimal stock levels prevents overstocking, which ties up capital and increases storage costs. Implementing a system for tracking inventory levels in real-time allows businesses to anticipate demand and avoid stockouts, which can lead to lost sales and dissatisfied customers. This proactive approach also helps to reduce waste by minimizing spoilage and obsolescence.

A key aspect of inventory management is forecasting demand accurately. Understanding historical sales trends, seasonal variations, and market fluctuations allows businesses to adjust their inventory levels accordingly. This leads to improved cash flow management and reduces the risk of holding excess inventory. By carefully monitoring and adjusting inventory levels, businesses can optimize their supply chain and minimize associated costs.

Procurement Optimization

Negotiating favorable contracts with suppliers is a cornerstone of cost minimization. Developing strong relationships with reliable suppliers can lead to significant price reductions and improved delivery times. Businesses can leverage bulk purchasing discounts and explore alternative suppliers to find the best possible deals. This proactive approach ensures competitive pricing and reduces the overall cost of goods.

Analyzing supplier performance and identifying areas for improvement is essential. Monitoring delivery times, product quality, and communication effectiveness can help businesses identify and address potential issues. This analysis can lead to better negotiation strategies and potentially further reductions in procurement costs.

Process Efficiency Improvements

Streamlining internal processes is critical for cost reduction. Identifying and eliminating bottlenecks in workflows can significantly improve productivity and reduce operational costs. Implementing efficient systems for order processing, manufacturing, and customer service can significantly improve overall efficiency and reduce labor costs. This can also lead to improved customer satisfaction and potentially increased sales revenue.

Automation of repetitive tasks is another effective way to improve process efficiency. Automating tasks like data entry, order fulfillment, and customer service responses can free up valuable employee time and reduce labor costs. This frees up employees to focus on higher-value tasks and contributes to overall operational efficiency.

Pricing Strategies

Developing a robust pricing strategy can directly influence profitability. Conducting market research to understand competitor pricing and consumer demand is essential for setting competitive and profitable prices. Pricing strategies should consider production costs, overhead expenses, and desired profit margins. This ensures that prices are aligned with market values and contribute to maximizing revenue.

Implementing dynamic pricing strategies can further optimize revenue. Adjusting prices based on demand, time of day, or other factors can maximize revenue generated from each sale. This approach requires careful monitoring and analysis of market trends to maintain profitability.

Technology Adoption

Leveraging technology can significantly enhance operational efficiency and reduce costs. Implementing Enterprise Resource Planning (ERP) systems can streamline business processes, improve data management, and enhance communication between departments. This allows for better decision-making based on real-time data and reduces the risk of errors.

Exploring cloud-based solutions for storage and computation can reduce infrastructure costs. Cloud-based solutions often offer scalability and flexibility, allowing businesses to adapt to changing needs without significant upfront investment. These solutions can also reduce the need for extensive IT staff and associated costs.

Employee Training and Development

Investing in employee training and development can lead to increased productivity and efficiency. Trained employees are better equipped to handle complex tasks, reducing errors and improving overall output. This can lead to reduced operational costs and increased profitability. Employee training can also improve employee morale and reduce employee turnover, which in itself saves costs associated with recruitment and onboarding.

Developing employee skill sets relevant to specific business needs can improve operational efficiency. Training employees in advanced techniques, new software, or industry best practices can significantly enhance their performance. This can lead to improved productivity, reduced errors, and ultimately lower costs associated with operations.

Supplier Relationship Management

Strong supplier relationships are essential for minimizing costs. Building strong relationships with suppliers can lead to better pricing, improved delivery times, and greater product quality. This can result in overall cost savings and improved reliability. A good supplier relationship can also provide valuable insights into market trends and emerging technologies, allowing businesses to stay ahead of the curve and adjust their strategies accordingly.

Regular communication and collaboration with suppliers can lead to better understanding of their capabilities and capacity. This can help businesses to anticipate potential supply chain disruptions and mitigate risks. Strong supplier relationships can contribute to a more resilient and cost-effective supply chain.

Read more about Eco Friendly Building Materials: Performance and Cost

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing