Smart Building HVAC Optimization with AI

Data Ingestion and Preparation

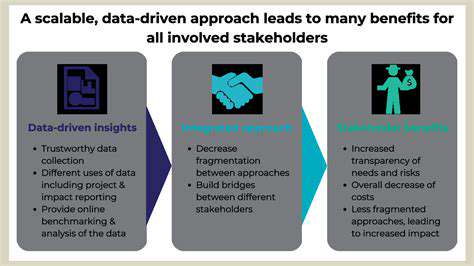

A crucial first step in any AI-driven optimization strategy for smart buildings is robust data collection. This involves meticulously gathering data from various sources, including sensor readings, occupancy patterns, energy consumption logs, and building management system (BMS) data. The quality and quantity of this initial data directly impact the accuracy and effectiveness of subsequent analyses and predictive models. Thorough data cleaning, transformation, and formatting are essential to ensure data integrity and compatibility with the chosen AI algorithms. This preparatory phase often requires significant effort and careful consideration, but it lays the foundation for successful AI-powered optimization.

Different building systems generate data in various formats. Integrating these diverse data streams into a unified platform is a critical challenge. This often involves data standardization and harmonization to ensure consistency and compatibility across the different sources. For instance, sensor readings from different types of equipment might have different units or formats. Standardization ensures that the data is comparable and usable for analysis, facilitating the development of accurate models and informed decisions. Data validation is also paramount to ensure the reliability and trustworthiness of the collected information.

Predictive Modeling and Forecasting

Once the data is prepared, the next stage involves developing predictive models to forecast future building performance. These models leverage machine learning algorithms to identify patterns and relationships within the data. For example, models can predict energy consumption based on occupancy levels, weather conditions, and time of day. This predictive capability allows building managers to proactively optimize energy usage, minimizing waste and maximizing efficiency.

Building occupancy patterns, climate conditions, and other external factors can be integrated into predictive models to anticipate energy demands. Accurate forecasting enables proactive adjustments in building systems, such as lighting, HVAC, and security. These adjustments can significantly impact energy efficiency and cost savings. Moreover, the models can identify potential issues and predict maintenance needs, leading to preventive maintenance strategies that extend the lifespan of building equipment and minimize downtime.

Performance Evaluation and Optimization

Evaluating the performance of the AI-driven optimization strategies is critical to ensure their effectiveness. Key performance indicators (KPIs) such as energy consumption, cost savings, and occupant satisfaction should be monitored and analyzed. Regular performance evaluations allow for adjustments to the models and strategies based on real-world data. By continuously monitoring and refining the AI-powered optimization, building managers can achieve greater efficiency and cost savings.

The results of the model predictions must be rigorously tested against actual building performance data. The analysis should include metrics like energy consumption, carbon emissions, and occupant comfort. This iterative process of evaluation and refinement ensures that the AI-driven optimization strategies remain relevant and effective over time. Feedback loops are essential to incorporate the insights gained from the analysis into future optimizations, creating a dynamic and adaptive system.

Real-Time Monitoring and Control

Integrating real-time monitoring and control systems with the AI models is essential for achieving continuous optimization. This allows for immediate adjustments to building systems based on the predictions and insights generated by the AI. The ability to respond dynamically to changing conditions, such as fluctuating energy prices or unexpected weather events, is crucial for maximizing efficiency.

AI-driven control systems can automatically adjust HVAC parameters, lighting levels, and other building systems in real-time. This responsiveness enables the building to adapt to varying conditions, optimize resource usage, and minimize waste. The real-time monitoring also facilitates the detection of anomalies and potential issues, enabling prompt intervention and preventing costly disruptions or failures.

Predictive Maintenance for Proactive System Management

Predictive Maintenance: A Revolution in Industrial Operations

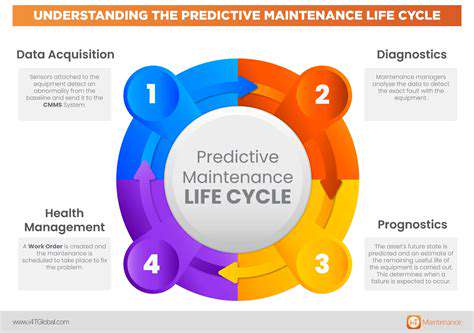

Predictive maintenance is rapidly transforming industrial operations by moving beyond reactive fixes to proactive strategies. It leverages data analysis and machine learning algorithms to forecast equipment failures, allowing for preventative maintenance interventions. This proactive approach significantly reduces downtime, minimizes costly repairs, and enhances overall equipment effectiveness (OEE).

Data Collection and Analysis: The Foundation of Predictive Maintenance

The core of predictive maintenance lies in meticulously collecting and analyzing data from various sources. This includes sensor data from machinery, operational logs, and even weather patterns that can impact equipment performance. Sophisticated algorithms then identify patterns and anomalies, providing valuable insights into potential equipment failures.

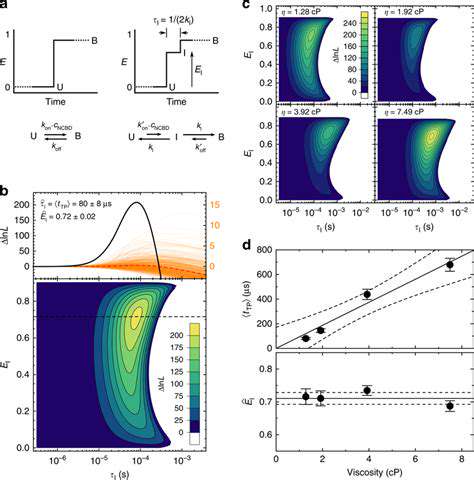

Machine Learning Models for Accurate Predictions

Machine learning algorithms are crucial in predictive maintenance, enabling accurate predictions of equipment failures. These algorithms learn from historical data to identify trends and patterns that indicate impending failures, allowing for timely interventions. Different machine learning models, such as regression, classification, and clustering, are employed depending on the specific needs of the industrial process.

Real-Time Monitoring and Alert Systems

Predictive maintenance systems often incorporate real-time monitoring tools that track equipment performance. These systems generate alerts when anomalies are detected, enabling timely interventions to prevent costly breakdowns. This real-time monitoring ensures that any issues are addressed promptly, minimizing disruptions to production.

Improved Equipment Reliability and Reduced Downtime

Implementing predictive maintenance strategies directly impacts equipment reliability and reduces downtime. By anticipating potential failures, maintenance teams can perform preventative actions before major breakdowns occur, thereby minimizing production disruptions and maximizing operational efficiency. This proactive approach leads to a significant reduction in unexpected downtime, saving substantial time and resources.

Cost Savings and Enhanced Operational Efficiency

The cost savings associated with predictive maintenance are substantial. By minimizing unplanned downtime and preventing catastrophic failures, businesses can significantly reduce maintenance costs. Furthermore, predictive maintenance optimizes operational efficiency by reducing the frequency of unplanned repairs and increasing equipment uptime, leading to higher productivity. This translates to a more sustainable and profitable industrial operation.

Future Trends and Applications in Predictive Maintenance

The future of predictive maintenance is bright, with ongoing advancements in data analytics and machine learning. These advancements will continue to improve the accuracy of predictions and the efficiency of maintenance procedures. Applications are expanding beyond industrial machinery to include other critical infrastructure, such as power grids and transportation systems. The ability to anticipate and address potential failures in these systems will be crucial for maintaining safety and reliability in the future.

Read more about Smart Building HVAC Optimization with AI

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing