Smart Building Predictive Maintenance for HVAC

Solar energy, a clean and abundant resource, is increasingly being integrated into automotive manufacturing. Solar panels can power various aspects of the production process, from charging electric vehicle batteries to powering assembly line machinery. This reduces reliance on fossil fuels and lowers carbon emissions throughout the manufacturing lifecycle. The use of solar energy also creates a more sustainable and environmentally friendly manufacturing environment, aligning with global efforts to combat climate change and reduce the industry's overall carbon footprint. By harnessing sunlight, manufacturers can significantly decrease their dependence on traditional energy sources and contribute to a greener future.

Implementing Predictive Maintenance in Smart Building Environments

Predictive Maintenance: A Paradigm Shift in Building Management

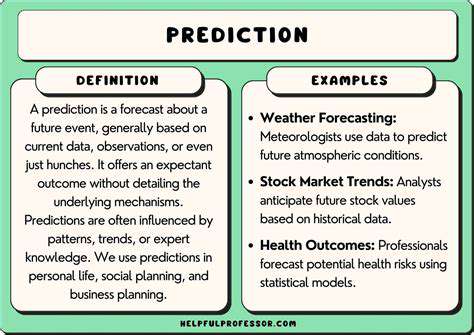

Predictive maintenance, a proactive approach to maintenance, moves beyond reactive responses to equipment failures. Instead of waiting for equipment to break down, predictive maintenance analyzes data from various sources within a smart building environment to anticipate potential failures and schedule maintenance accordingly. This proactive strategy minimizes downtime, reduces repair costs, and extends the lifespan of building systems. By identifying patterns and anomalies in data, predictive maintenance systems can forecast when equipment is likely to require maintenance, allowing for preventative measures to be taken before significant issues arise.

Data Sources for Predictive Maintenance in Smart Buildings

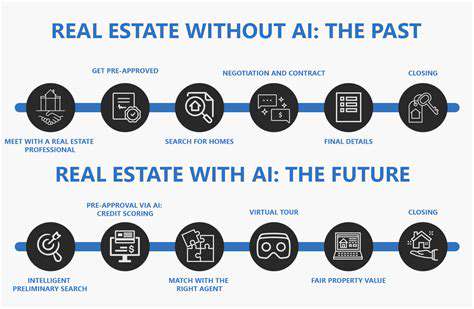

A crucial aspect of implementing predictive maintenance in smart buildings is identifying and utilizing reliable data sources. This includes sensor data from HVAC systems, lighting, security systems, and structural components. Analyzing data from these sources, along with historical maintenance records and environmental factors, provides a comprehensive understanding of equipment performance and potential failure points. Integrating data from building automation systems (BAS), IoT devices, and even weather patterns allows for a more nuanced understanding of equipment behavior and enables more accurate predictions.

Furthermore, integrating data from occupancy sensors, energy consumption patterns, and even social media insights can provide additional context for predictive maintenance. For example, if a sudden spike in energy consumption in a specific area is detected, it might trigger a predictive maintenance alert for potential equipment malfunction. The combination of these diverse data sources provides a holistic view of building operations, enabling more effective and efficient maintenance strategies.

Benefits of Implementing Predictive Maintenance

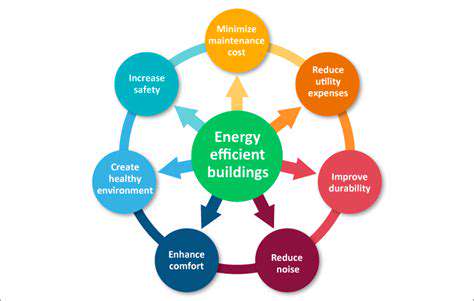

The benefits of implementing predictive maintenance in smart buildings are multifaceted and substantial. Reduced downtime is a primary advantage, as maintenance schedules are optimized to minimize disruptions to building operations. This translates to significant cost savings by avoiding unexpected breakdowns and costly emergency repairs. Moreover, predictive maintenance extends the lifespan of building systems, reducing the need for premature replacements. This not only saves money but also minimizes environmental impact by prolonging the useful life of existing infrastructure.

Improved energy efficiency is another key benefit. By anticipating maintenance needs, predictive maintenance systems can optimize energy consumption patterns. Early detection of equipment issues can prevent energy-wasting inefficiencies. This proactive approach results in substantial energy savings and a reduced carbon footprint, aligning with sustainability goals in the smart building environment. Improved safety and reduced risk of equipment failures are also significant benefits of predictive maintenance, enhancing the safety of building occupants and personnel.

Challenges and Considerations for Implementation

Implementing predictive maintenance in smart buildings, while offering significant advantages, also presents some challenges. One major consideration is the substantial investment required for sensors, data analytics platforms, and skilled personnel to manage and interpret the data. Ensuring data security and privacy is another critical aspect, as smart buildings collect and store vast amounts of sensitive data. Integration with existing building management systems and ensuring interoperability between different systems is also crucial for successful implementation. Finally, the need for ongoing training and education to ensure staff can effectively utilize the predictive maintenance system is essential for success.

Read more about Smart Building Predictive Maintenance for HVAC

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing