Smart Building Predictive Maintenance: Saving Costs

Predicting Equipment Failures with Machine Learning

Understanding the Problem

Predictive maintenance stands as a cornerstone for optimizing building operations and minimizing costly downtime. When HVAC systems, elevators, or lighting fixtures fail unexpectedly, the consequences ripple through tenant satisfaction, operational workflows, and financial planning. By analyzing subtle patterns and emerging anomalies, facility managers gain the foresight needed to prevent catastrophic breakdowns and expensive emergency repairs.

Anticipating equipment failures transforms maintenance from reactive to strategic. Scheduled interventions based on predictive insights not only prevent operational chaos but also extend the productive lifespan of critical building assets. This paradigm shift delivers measurable cost savings while elevating overall system reliability.

Data Collection and Preparation

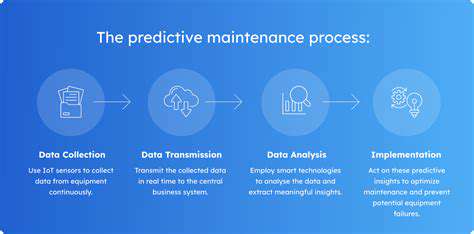

The foundation of any robust predictive system lies in comprehensive data acquisition. Modern smart buildings generate streams of operational intelligence from networked sensors - temperature readings, pressure fluctuations, vibration signatures, and dozens of other performance metrics. Data scientists must approach this wealth of information with meticulous care, addressing gaps, anomalies, and inconsistencies through rigorous preprocessing protocols.

Effective data conditioning separates successful implementations from failed experiments. Beyond basic cleaning, feature engineering unlocks hidden predictive power by creating meaningful derived variables that machine learning algorithms can leverage for more accurate forecasting.

Choosing the Right Machine Learning Models

The machine learning toolkit offers diverse approaches for failure prediction, each with unique strengths. While Random Forests provide excellent interpretability, Neural Networks excel at detecting complex nonlinear patterns in multivariate time-series data. The selection process must balance algorithmic sophistication with practical considerations like computational efficiency and explainability requirements.

Model validation remains paramount - sophisticated algorithms mean little without demonstrated real-world predictive power. Cross-validation techniques and holdout testing provide the necessary checks against overfitting and ensure reliable performance across different equipment types and operating conditions.

Model Training and Evaluation

The training phase represents where theoretical models transform into practical tools. Through iterative adjustment cycles, algorithms learn to correlate subtle changes in sensor data with impending equipment issues. This phase demands both technical expertise and domain knowledge to properly tune hyperparameters and avoid common pitfalls like data leakage.

Evaluation metrics tell the true story of model effectiveness. Beyond simple accuracy, precision-recall curves and AUC scores provide nuanced insights into how well the system distinguishes between normal operation and developing faults. These metrics guide continuous refinement to achieve operational-grade reliability.

Deployment and Monitoring

Integration with existing building management systems presents both technical and organizational challenges. The most sophisticated model provides no value unless it can deliver actionable alerts to maintenance teams through familiar interfaces. Real-time performance monitoring transforms static predictions into dynamic risk management, with automated alerts prioritizing the most critical intervention points.

Continuous model retraining ensures the system adapts to changing conditions - equipment aging, seasonal variations, and even modifications to building use patterns. This living approach maintains predictive accuracy as the building ecosystem evolves over time.

Real-World Applications and Benefits

The tangible impacts of predictive maintenance reshape facility economics. Operational disruptions shrink dramatically when maintenance occurs on schedule rather than during crises. Beyond cost avoidance, these systems create compounding value through extended equipment lifecycles, optimized energy consumption, and data-driven capital planning.

Forward-thinking organizations leverage these insights for strategic advantage, transforming maintenance from a cost center into a value driver. The resulting efficiency gains contribute meaningfully to sustainability goals while improving the bottom line through smarter resource allocation.

Read more about Smart Building Predictive Maintenance: Saving Costs

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing