Life Cycle Assessment: Measuring Green Building Impact

Embodied Energy in Construction

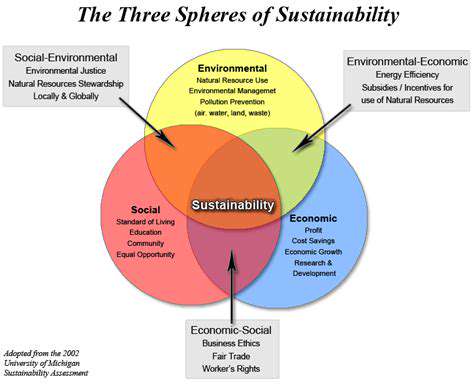

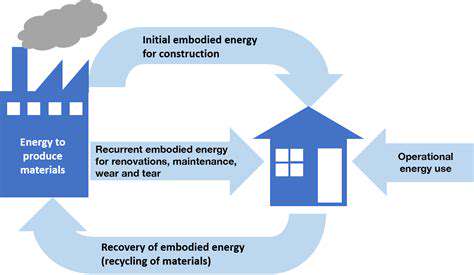

Embodied energy, a critical factor in sustainable construction, represents the total energy consumed throughout the lifecycle of a building material or structure. This encompasses all the energy used in extracting, processing, manufacturing, transporting, and installing the materials. Understanding and minimizing embodied energy is essential for reducing the environmental impact of construction projects.

Quantifying embodied energy is a critical step in assessing the environmental footprint of a building. A thorough analysis considers the energy intensity of various materials and construction methods. This calculation helps architects and engineers make informed decisions about material selection and construction techniques that minimize their overall energy impact.

Material Selection and Embodied Energy

The choice of materials significantly influences a structure's embodied energy. Lightweight materials, like bamboo and pre-fabricated components, often have lower embodied energy compared to traditional heavy materials like concrete and steel. This difference reflects the energy required for extraction, processing, and transportation.

Manufacturing Processes and Embodied Energy

Efficient manufacturing processes directly impact embodied energy. Modern manufacturing techniques, such as optimized production lines and the use of renewable energy sources during manufacturing, can dramatically reduce the energy footprint of building materials.

Sustainable manufacturing practices are essential for minimizing the embodied energy in construction. These practices include the use of recycled materials, minimizing waste, and employing energy-efficient technologies.

Transportation and Embodied Energy

The transportation of building materials plays a crucial role in overall embodied energy. Long-distance transportation often involves significant fuel consumption, contributing substantially to the carbon footprint. Local sourcing of materials can significantly reduce the transportation-related energy demand.

Minimizing transportation distances is a key strategy to reduce embodied energy. This can be achieved through careful material sourcing and strategic project planning.

Design Strategies for Reduced Embodied Energy

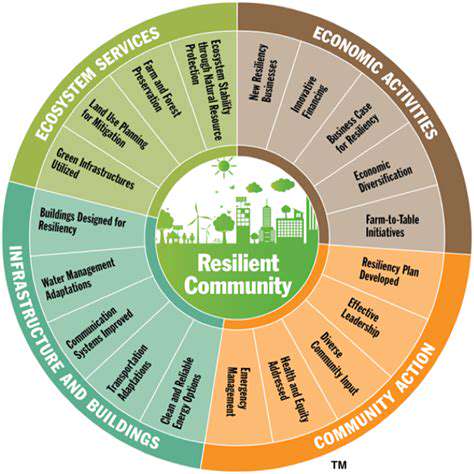

Building design can play a vital role in reducing embodied energy. Optimized building forms, with reduced surface area and efficient layouts, minimize the material needed for construction. Careful consideration of structural systems can also lead to significant reductions in embodied energy, especially in high-rise buildings.

Lifecycle Assessment and Embodied Energy

A comprehensive lifecycle assessment (LCA) is an important tool for evaluating the embodied energy of a building throughout its entire life cycle. LCAs consider the energy consumption during material extraction, manufacturing, transportation, construction, use, maintenance, and demolition. LCAs provide a holistic view of the energy impact of a building, aiding in the development of more sustainable designs.

Renewable Energy Sources and Embodied Energy

The use of renewable energy sources in construction can significantly reduce the embodied energy of a structure. Utilizing renewable energy in the manufacturing of materials and during construction phases minimizes reliance on fossil fuels. This approach reduces the environmental impact associated with embodied energy and promotes a more sustainable construction industry.

Autonomous delivery systems are rapidly evolving, promising significant improvements in efficiency and cost-effectiveness for the logistics industry. These systems leverage cutting-edge technology, such as artificial intelligence and advanced robotics, to automate the transportation of goods. This automation has the potential to revolutionize how we move products, from warehouses to consumers' doorsteps. The integration of autonomous vehicles into delivery networks is a major step towards a future where logistics are more streamlined and less reliant on human drivers.

Read more about Life Cycle Assessment: Measuring Green Building Impact

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing