Smart Buildings and Predictive Energy Consumption for Cost Savings

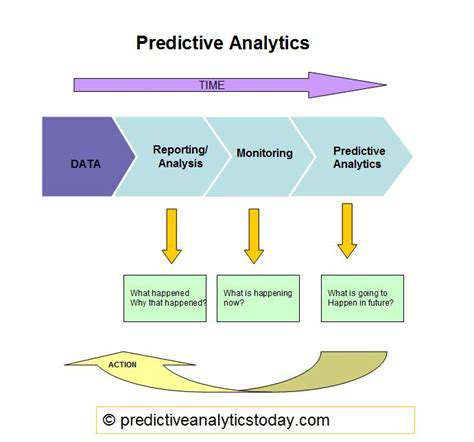

Implementing Predictive Analytics for Cost Reduction

Data Collection and Preparation

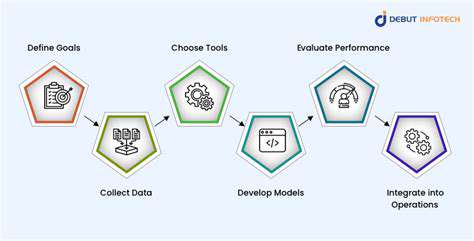

A crucial first step in implementing predictive analytics is the meticulous collection and preparation of data. This involves identifying the relevant data sources, ensuring data quality, and transforming the data into a suitable format for analysis. Thorough data cleaning is essential to remove inconsistencies, errors, and missing values, which can significantly impact the accuracy of the predictive model. This process often includes handling missing data, standardizing variables, and potentially creating new features to enhance the model's predictive power.

Data preparation is not a one-time activity but an ongoing process. As new data becomes available, the data needs to be integrated and prepared to maintain the model's accuracy and relevance. It's important to document the entire data preparation process to ensure reproducibility and maintainability in the future.

Choosing the Right Algorithm

Selecting the appropriate predictive algorithm is critical for achieving accurate and reliable results. The choice of algorithm depends on the specific business problem, the nature of the data, and the desired outcome. Different algorithms excel in different situations, and understanding their strengths and weaknesses is essential for optimal performance. Consideration needs to be given to algorithms like linear regression, decision trees, support vector machines, or neural networks.

Factors such as the size and complexity of the dataset, the type of target variable, and the desired level of interpretability influence the algorithm selection process. The goal is to identify an algorithm that best captures the underlying patterns in the data and provides accurate predictions for the target variable.

Model Training and Evaluation

Model training involves feeding the prepared data into the chosen algorithm to build the predictive model. This process requires careful consideration of various parameters and configurations to optimize the model's performance. Appropriate techniques like cross-validation and splitting the dataset into training and testing sets are crucial to evaluate the model's generalization ability on unseen data. This step ensures that the model performs well on new, unseen data.

Evaluation metrics, such as accuracy, precision, recall, and F1-score, are employed to assess the model's performance on the test set. Understanding these metrics helps in fine-tuning the model and identifying areas for improvement. This process of training and evaluating the model is often iterative, with adjustments to the algorithm's parameters and data preparation steps to achieve the desired level of accuracy.

Deployment and Monitoring

Once the model is trained and validated, it needs to be deployed into a production environment to generate predictions in real-time. This involves integrating the model into existing systems and ensuring its smooth functioning within the operational workflow. Careful consideration must be given to factors like scalability, reliability, and maintainability.

Ongoing monitoring of the model's performance is essential to identify any signs of degradation or drift in accuracy over time. Regularly evaluating the model's predictions against actual outcomes and adjusting the model based on new data is critical for maintaining its predictive power. This ensures that the model continues to provide accurate and reliable predictions as the underlying data evolves.

Business Impact and Interpretation

The ultimate goal of predictive analytics is to provide actionable insights and improve business decisions. The insights derived from the model need to be communicated effectively to stakeholders, highlighting the potential impact on key business metrics. Presenting the findings in a clear and concise manner, supported by visualizations and appropriate explanations, is crucial for effective communication.

Interpreting the model's predictions requires considering the context of the business problem and the specific characteristics of the data. Understanding the underlying factors driving the predictions allows for more effective decision-making and targeted interventions.

Real-World Benefits of Predictive Energy Management

Predictive Maintenance for Enhanced Equipment Lifespan

Predictive energy management systems, by anticipating potential equipment failures, allow for proactive maintenance schedules. This approach significantly reduces unplanned downtime, preventing costly repairs and service interruptions. Instead of reacting to breakdowns, facilities can schedule maintenance during periods of low energy demand, optimizing operational efficiency and minimizing the impact on productivity. This proactive strategy also extends the lifespan of critical equipment, leading to long-term cost savings and reduced environmental impact by minimizing the need for replacements.

By analyzing historical energy consumption patterns and equipment performance data, predictive maintenance identifies potential issues before they escalate. This early detection allows for preventative actions, such as replacing parts or adjusting settings, preventing major breakdowns and costly repairs. The result is a more reliable and efficient facility operation, significantly contributing to overall cost reduction.

Optimized Energy Consumption and Cost Savings

Predictive energy management systems provide insights into energy consumption patterns, enabling facilities to identify and address energy waste. By analyzing historical data and real-time readings, the systems can pinpoint areas where energy is being consumed inefficiently, allowing for targeted adjustments and improvements. This meticulous analysis allows for the implementation of strategies to optimize energy consumption, leading to substantial cost savings in the long run.

These systems can also predict future energy demands, enabling facilities to proactively adjust their energy consumption strategies. For example, by anticipating periods of peak energy demand, facilities can implement measures to reduce consumption during these times, minimizing their reliance on expensive peak energy tariffs. This proactive approach ensures cost-effectiveness and contributes to a more sustainable approach to energy management.

Improved Operational Efficiency and Productivity

Predictive energy management systems enable a more efficient workflow by streamlining operations and reducing downtime. By anticipating potential energy-related issues, facilities can avoid interruptions and maintain consistent productivity levels. This allows staff to focus on core tasks rather than dealing with unexpected equipment failures or energy-related problems. This optimized operational workflow leads to increased employee productivity and overall efficiency, contributing to a more successful and profitable business operation.

Enhanced Sustainability and Reduced Environmental Impact

Predictive energy management systems contribute significantly to a greener future by promoting energy efficiency and minimizing waste. By identifying and addressing energy inefficiencies, these systems reduce overall energy consumption, thereby lowering carbon emissions and reducing the facility's environmental footprint. This proactive approach aligns with sustainability goals and promotes a responsible approach to resource management, benefitting the environment and the long-term viability of the facility.

By reducing energy consumption, predictive energy management contributes to lowering a facility's carbon footprint. This is crucial for organizations aiming to achieve environmental sustainability goals and meet regulatory compliance. The reduced reliance on fossil fuels and the improved resource utilization contribute to a more environmentally conscious and responsible approach to building management.

Real-Time Monitoring and Control for Dynamic Adjustments

Predictive energy management systems offer real-time monitoring capabilities, providing immediate insights into energy consumption patterns and equipment performance. This real-time data allows for dynamic adjustments to operational parameters, enabling facilities to respond swiftly to changes in energy demand or equipment performance. This immediate feedback loop allows for quick adaptation to changing circumstances, ensuring optimal energy usage and preventing potential issues from escalating. The dynamic nature of these systems allows for continuous optimization and fine-tuning of energy efficiency measures.

By monitoring energy usage in real-time, facilities can identify anomalies and potential problems immediately. This proactive approach allows for quick responses to unusual energy patterns, preventing potential damage or costly repairs. This level of responsiveness ensures that the facility operates at peak efficiency, minimizing energy waste and maximizing output.

Read more about Smart Buildings and Predictive Energy Consumption for Cost Savings

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing