Sustainable Construction Materials: Recycled Content

Introduction to the Growing Importance of Recycled Materials

Understanding the Environmental Impact of Traditional Construction Materials

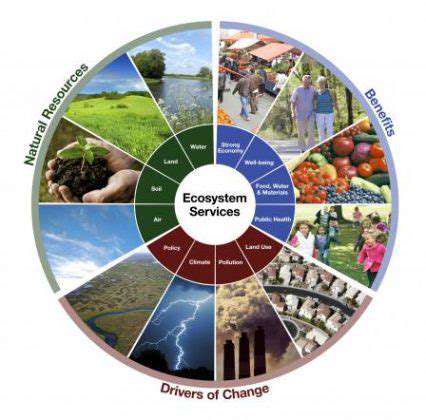

Construction practices have long depended on virgin resources, but the environmental toll is becoming impossible to ignore. When we extract materials like timber, concrete, and metals, we're not just taking from the earth - we're triggering a chain reaction of ecological damage. The energy-intensive processes behind these materials leave scars on landscapes while pumping greenhouse gases into our atmosphere. What many don't realize is that these conventional methods don't just affect the environment during extraction - the manufacturing phase introduces toxic chemicals into our waterways and air, creating health risks that persist long after construction crews leave the site.

We're facing a critical turning point where our appetite for new materials outpaces what the planet can sustainably provide. The construction sector must confront this reality head-on by embracing recycled alternatives. Every ton of recycled material we use represents resources kept in the ground and pollution kept out of our ecosystems. This shift isn't just environmentally responsible - it's becoming an economic necessity as raw material costs continue to climb.

The Advantages of Using Recycled Materials in Construction

The case for recycled materials extends far beyond environmental benefits. Builders are discovering that these alternatives often outperform their conventional counterparts while saving money. Recycled concrete aggregates, for instance, frequently demonstrate greater durability than newly mined stone. The economic advantages become even clearer when considering the reduced transportation costs for locally sourced recycled materials versus imported virgin resources.

Innovation in material science is unlocking exciting possibilities for recycled content. Architects now have access to stunning design elements crafted from repurposed glass and metals, while engineers develop structural components using recycled plastics with enhanced weather resistance. The construction industry is witnessing a quiet revolution where waste streams become valuable inputs, challenging our traditional notions of what building materials should look like and how they should perform.

Perhaps most importantly, these materials create a feedback loop of sustainability. As demand grows, recycling infrastructure improves, creating better quality materials at lower costs. This virtuous cycle makes sustainable construction increasingly accessible for projects of all scales.

The Practical Applications and Future Trends of Recycled Construction Materials

Walk through any modern construction site today, and you'll likely encounter recycled materials in surprising applications. Roofing tiles containing recycled rubber, insulation made from denim scraps, and structural beams incorporating recycled steel are becoming commonplace. These aren't niche products anymore - they're mainstream solutions that meet or exceed building code requirements while reducing environmental impact.

The trajectory points toward even greater adoption in coming years. As municipalities implement stricter sustainability requirements and consumers demand greener buildings, recycled materials will shift from optional to essential. Forward-thinking developers are already using material reuse as a competitive advantage, marketing their projects' lower carbon footprints to environmentally conscious buyers. This trend will only accelerate as recycling technologies improve and the true cost of virgin material extraction becomes more apparent.

Economic Advantages and the Circular Economy

Economic Advantages of a Circular Economy

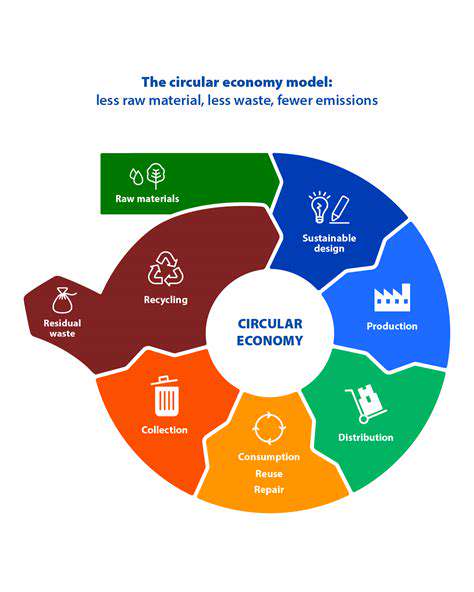

The circular economy represents more than environmental stewardship - it's a fundamental rethinking of how value flows through our economic systems. Companies leading this transition are discovering that waste reduction directly translates to profit enhancement. By designing products for disassembly and reuse, businesses create multiple revenue streams from what was previously considered trash. The economic benefits compound when you consider reduced liability from hazardous waste disposal and improved brand value among sustainability-minded consumers.

Supply chain resilience emerges as another critical advantage. In a world of increasing resource scarcity and geopolitical instability, companies relying on recycled inputs enjoy more predictable costs and reliable material availability. This stability becomes a strategic asset when competitors struggle with volatile commodity prices. The circular model also fosters innovation - constraints breed creativity, leading to breakthrough products that open new markets.

Circular Economy and Job Creation

The employment potential of the circular economy often gets overlooked in policy discussions. For every job lost in extractive industries, multiple new positions emerge in material recovery, remanufacturing, and sustainable design. These tend to be local jobs that can't be outsourced - after all, recycling facilities need to be near the communities they serve. The skills required span from high-tech sorting system operators to artisans transforming discarded materials into premium products.

Small businesses are finding particularly fertile ground in this transition. Neighborhood repair shops, upcycling studios, and material exchange platforms represent the grassroots of the circular economy. These enterprises often serve as incubators for innovative business models that larger companies later adopt. The result is a more diverse economic ecosystem that values resourcefulness as much as productivity.

Educational institutions are responding to these shifts by developing new curricula around circular design and sustainable materials management. This creates pathways for workers to transition from sunset industries to growing sectors, ensuring the workforce evolves alongside the economy.

Read more about Sustainable Construction Materials: Recycled Content

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing