AI Powered Valuation: The Key to Smarter Real Estate Deals

Beyond Traditional Appraisal Methods: Exploring Modern Alternatives

Traditional appraisal methods, while established, often fall short in capturing the nuances of the modern real estate market. These methods may not fully account for factors like location-specific trends, evolving property usage, or the impact of technology on value. This necessitates the exploration of alternative approaches that offer a more comprehensive and dynamic perspective on property valuation.

Modern alternatives to traditional appraisal methods are crucial for providing accurate and up-to-date valuations. These methods incorporate a broader range of data sources and analytical techniques to better reflect the complexities of today's real estate landscape.

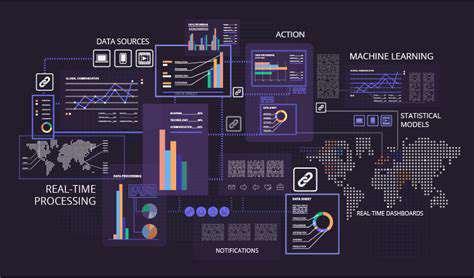

Data-Driven Insights for Enhanced Accuracy

Leveraging data analytics offers a significant advancement in appraisal accuracy. By employing sophisticated algorithms and machine learning techniques, appraisers can analyze vast datasets encompassing market trends, comparable sales, and property-specific characteristics. This data-driven approach significantly improves the precision and reliability of valuations.

The Role of Market Analysis in Modern Appraisals

A comprehensive market analysis is fundamental to modern appraisal methodologies. This involves a thorough examination of local market conditions, including recent sales activity, rental rates, and construction costs. By incorporating these insights, appraisers gain a deeper understanding of market dynamics and their impact on property values.

Analyzing these factors provides crucial context for assessing a property's worth, ensuring a more accurate reflection of the current market realities.

Utilizing Comparable Sales Data with Advanced Techniques

Modern appraisal methods place greater emphasis on the meticulous analysis of comparable sales data. Advanced techniques, like statistical modeling and predictive analytics, are employed to identify and adjust for discrepancies between comparable properties and the subject property. This refinement ensures a more accurate and reliable valuation.

Impact of Location-Specific Factors on Property Value

Location-specific factors significantly influence property values. Modern appraisal methods effectively consider these factors, including proximity to amenities, transportation networks, and local zoning regulations. Incorporating these factors into the valuation process is crucial for achieving a more realistic assessment of a property's worth.

The Influence of Technological Advancements on Appraisal Practices

Technological advancements have revolutionized appraisal practices. The use of online platforms, geographic information systems (GIS), and remote sensing technologies empowers appraisers to collect and analyze data more efficiently and comprehensively. This results in faster and more accurate valuations.

Integrating Expert Opinions and Local Knowledge

In addition to data-driven analysis, modern appraisal methods recognize the value of expert opinions and local market knowledge. Appraisers incorporate insights from real estate agents, local market experts, and community stakeholders to gain a holistic understanding of the property's context. This integrative approach refines the valuation process, leading to a more nuanced and accurate assessment of value.

While a car's 0-60 mph time is a critical metric for gauging acceleration, it doesn't paint the entire picture of performance. Top speed, often overlooked, is a crucial element of an electric vehicle's overall capabilities. Factors like aerodynamic design, motor power, and battery capacity all play significant roles in determining a vehicle's ability to reach and maintain high speeds. A streamlined body reduces air resistance, a powerful motor generates torque at high RPMs, and a larger battery pack can supply the necessary energy for extended periods of high-speed operation. Understanding these interlinked factors is key to appreciating the full potential of an electric vehicle.

Predictive Analytics for Future Market Trends

Predictive Modeling Techniques

Predictive analytics for future manufacturing relies heavily on sophisticated modeling techniques. These techniques use historical data, combined with various algorithms, to forecast future trends and outcomes. Machine learning algorithms, such as regression, classification, and clustering, are particularly valuable in identifying patterns and relationships within the data. These models can be trained on data encompassing various aspects of manufacturing operations, including production rates, equipment performance, and material usage.

Different predictive models cater to diverse needs. For instance, regression models are effective in forecasting numerical values, like production output, while classification models are better suited for predicting categorical outcomes, such as equipment failures. By understanding the strengths and limitations of each technique, manufacturers can select the most appropriate model for their specific requirements and anticipated outcomes.

Data Collection and Preparation

A crucial aspect of successful predictive analytics lies in the quality and quantity of the data used to train the models. Robust data collection processes are essential to ensure accuracy and reliability of the analysis. This involves gathering data from various sources within the manufacturing environment, including sensor readings, maintenance records, and operational logs. The data must be meticulously cleaned and prepared before it can be used for model training. This involves handling missing values, outliers, and ensuring data consistency.

Data preparation is a significant step that often consumes considerable time and resources. Data must be transformed into a format that is suitable for the chosen model. This may involve feature engineering, where new variables are created from existing ones to improve model performance. Thorough data preparation is fundamental to the success of any predictive analytics initiative in manufacturing.

Implementation and Monitoring

Effective implementation of predictive analytics requires careful integration into existing manufacturing processes. This involves developing a clear strategy for using the predictions generated by the models. The insights gained from predictive analytics can be leveraged to optimize various aspects of the manufacturing process, such as scheduling, resource allocation, and maintenance planning.

Continuous monitoring and evaluation of the predictive models are also essential. As manufacturing conditions and processes evolve, the models need to be adapted and retrained to maintain accuracy. Regular performance assessments and adjustments ensure that the models remain relevant and useful in guiding future decisions.

Furthermore, establishing clear communication channels for sharing insights derived from the predictive models is critical. This allows for effective collaboration between different departments and stakeholders, facilitating the integration of predictive analytics into the overall manufacturing strategy.

Read more about AI Powered Valuation: The Key to Smarter Real Estate Deals

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

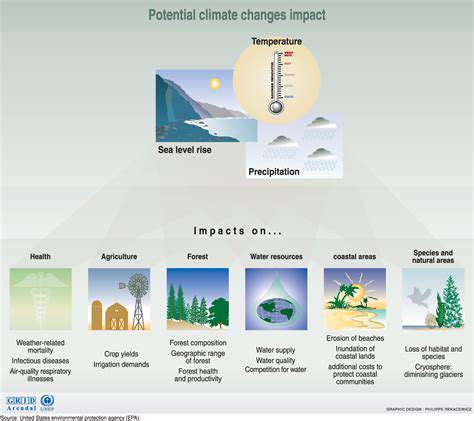

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing