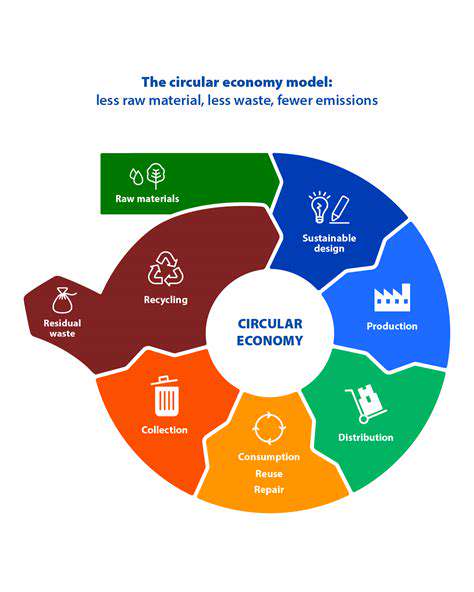

Circular Economy in Real Estate: Design for Disassembly

The Economic Imperative for Circularity

Forward-thinking developers now recognize circular practices as profit drivers rather than expenses. Amsterdam's Park 20|20 development demonstrates how material reuse can slash construction budgets by 15-20% while achieving premium rental rates. The project's success stems from three key strategies:

1. Establishing material banks for future reuse

2. Implementing modular office components

3. Creating standardized material passports

The business case strengthens when considering secondary markets—reclaimed brick commands 60-80% of new brick prices, while salvaged timber often exceeds original value as premium vintage material.

Design for Disassembly and Deconstruction

Pioneering architects now treat buildings as material libraries rather than permanent structures. The Lendager Group's Resource Rows project in Copenhagen showcases this philosophy, where 90% of materials came from demolished social housing. Their approach incorporates:

- Bolted connections instead of adhesives

- Standardized component sizes

- Material tracking through QR codes

This methodology enables selective dismantling that preserves material value, contrasting sharply with traditional wrecking ball demolition.

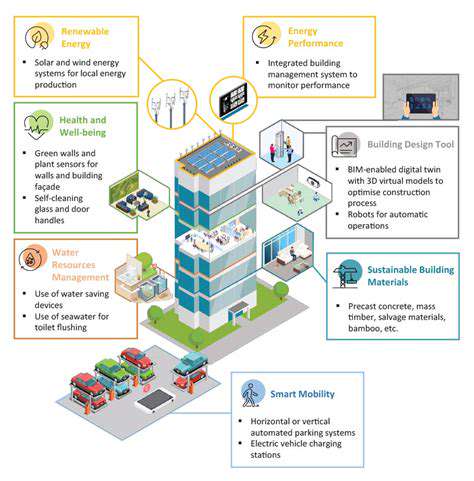

Material Selection and Sourcing for Sustainability

The circular revolution begins at the drawing board. Leading firms now evaluate materials through four lenses:

| Criterion | Example |

|---|---|

| Recycled content | Steel with 95%+ recycled material |

| Disassembly potential | Dry-assembled brick systems |

| Local availability | Regionally quarried stone |

| Chemical safety | Formaldehyde-free insulation |

Recent studies show buildings using these criteria achieve 30-50% lower embodied carbon while maintaining competitive construction timelines.

Waste Reduction and Management Strategies

Singapore's Zero Waste Masterplan provides a blueprint for construction sites, achieving 99% material recovery through:

- On-site sorting stations

- Just-in-time material delivery

- Prefabricated components

- Digital material tracking

These measures transform waste streams into revenue streams, with some contractors reporting 7-12% project cost savings from material resale.

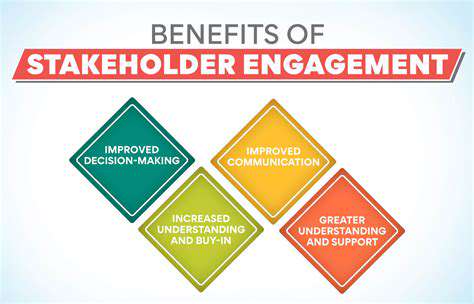

Community Engagement and Education

Rotterdam's Waste = Food initiative demonstrates how public participation accelerates circular adoption. The program:

- Trains residents in material sorting

- Hosts pop-up reuse centers

- Offers tax incentives for deconstruction

After three years, participating neighborhoods reduced construction waste by 73% while creating 200+ local recycling jobs.

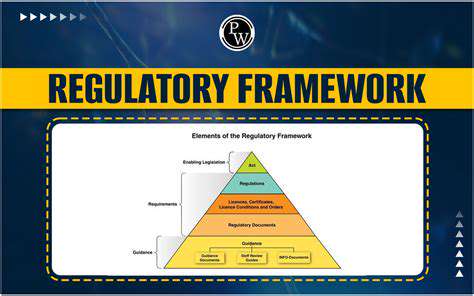

Policy and Regulatory Support

The EU's Circular Economy Action Plan sets global benchmarks with:

- Mandatory material passports by 2025

- 70% recycling targets for construction waste

- Tax breaks for circular buildings

Early adopters like Belgium report €2.3 billion in annual savings from reduced material imports and landfill costs.

Designing for Deconstruction: DfD in Action

DfD Principles in Building Materials

The Kendeda Building at Georgia Tech exemplifies material innovation, featuring:

- Nail-free timber connections

- Untreated structural elements

- Reversible mechanical fasteners

These features enable 90% material recovery versus 30% in conventional demolition, proving DfD's practical viability.

Modular Construction and DfD

Volumetric modular units revolutionize deconstruction. The Stack project in Brooklyn achieved:

| Metric | Result |

|---|---|

| Construction speed | 40% faster |

| Site waste | 83% reduction |

| Future adaptability | 5 reconfiguration cycles |

DfD and Structural Design

The Circle House in Denmark pioneers Lego-like construction with:

- Interlocking concrete elements

- Tool-free disassembly points

- Color-coded component systems

This design allows complete building disassembly in 3 days versus weeks for conventional demolition.

DfD and the Importance of Documentation

Material passports have evolved into sophisticated digital twins. The BAMB project's dynamic documentation includes:

- 3D scanning of connections

- Blockchain material tracking

- AR disassembly instructions

This reduces deconstruction planning time by 65% while ensuring maximum material recovery.

DfD and the Role of Collaboration

The London Energy Transformation Initiative created a cross-disciplinary DfD protocol involving:

| Stakeholder | Contribution |

|---|---|

| Architects | Connection detailing |

| Engineers | Load path analysis |

| Contractors | Sequencing plans |

| Demolition crews | Tool requirements |

DfD and the Economics of Deconstruction

Arup's cost-benefit analysis reveals compelling numbers:

- $18/sf savings in material recovery

- 12% faster site clearance

- 5-7% higher property values

These benefits compound over multiple building lifecycles, creating exponential value.

DfD and the Future of Sustainable Real Estate

As climate pressures intensify, DfD transitions from optional to essential. The World Green Building Council predicts:

- 50% of new builds will be DfD by 2030

- Material reuse markets will triple

- Deconstruction certifications will emerge

This shift represents the most significant construction evolution since reinforced concrete, permanently altering how we build our world.