Smart Building Management Systems: Next Gen Features

Enhanced Predictive Maintenance Capabilities

Implementation of Advanced Sensor Technologies

Today's predictive maintenance strategies depend on cutting-edge sensor technologies that keep a constant watch over equipment performance. These devices track critical metrics like temperature fluctuations, vibration levels, and pressure changes in real-time, allowing technicians to spot potential problems at their earliest stages. The adoption of ultra-precise sensing equipment has dramatically improved the reliability of maintenance forecasts. This technological evolution helps prevent costly breakdowns by identifying concerns before they develop into serious malfunctions.

Leveraging Machine Learning Algorithms

Sophisticated machine learning models process enormous volumes of sensor data to recognize patterns and irregularities that might signal approaching equipment issues. These intelligent systems continuously refine their predictive accuracy by learning from past operational data. The application of machine learning transforms maintenance planning from reactive to proactive, while optimizing how maintenance resources are distributed. This approach allows businesses to tackle potential problems in advance, reducing operational interruptions and prolonging equipment service life.

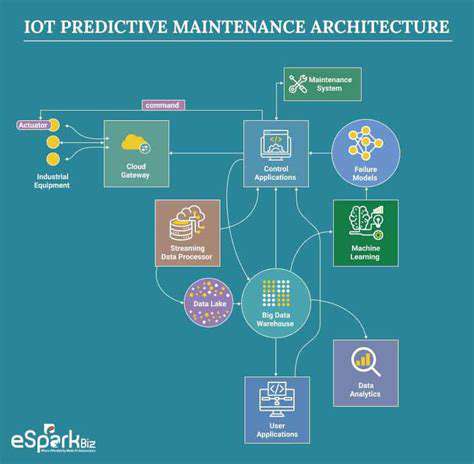

Integrating IoT for Real-Time Data Collection

The Internet of Things (IoT) serves as the critical link enabling smooth communication between monitoring devices and centralized maintenance platforms. IoT-connected equipment allows for instantaneous data transfer, giving maintenance personnel the ability to oversee machinery from anywhere and react quickly to developing situations. This networked infrastructure guarantees that maintenance choices are informed by up-to-the-minute information, boosting overall productivity. As IoT capabilities continue to advance, their incorporation into predictive maintenance approaches grows increasingly essential for maintaining peak operational performance.

Predictive Analytics and Decision-Making

Advanced predictive analytics employ sophisticated statistical models and data examination methods to anticipate equipment failures well before they happen. These valuable insights help maintenance crews make well-informed choices about the timing and nature of required interventions. The implementation of predictive analytics leads to more thoughtful planning and better management of maintenance assets. Companies can thereby eliminate unnecessary maintenance procedures while ensuring urgent matters receive immediate attention, thereby strengthening operational dependability.

Benefits of Enhanced Predictive Maintenance

Adopting improved predictive maintenance approaches delivers multiple advantages, including fewer unexpected shutdowns, reduced repair expenditures, and extended equipment durability. It also enhances workplace safety by stopping disastrous failures that could endanger employees. The resulting boost in operational productivity provides businesses with a distinct advantage in their markets. The implementation of these sophisticated methods is rapidly becoming the norm for progressive organizations focused on long-term sustainability and operational resilience.

Challenges and Future Directions

While offering numerous benefits, advanced predictive maintenance systems encounter obstacles including complicated data integration requirements, substantial upfront investment costs, and the necessity for specialized technical knowledge. Protecting sensitive operational data has also emerged as a significant concern as system connectivity expands. Future innovations will probably concentrate on developing more self-sufficient systems and artificial intelligence-powered diagnostic tools. These advancements will further perfect predictive maintenance functions, making them more widely available and efficient across diverse industries.

Seamless Integration with IoT Devices and Cloud Platforms

Seamless Data Flow for Enhanced Control

A fundamental characteristic of intelligent building management involves the smooth incorporation of information from multiple IoT devices and cloud services. This uninterrupted data exchange provides facility managers with immediate visibility into power usage, space utilization trends, and indoor environmental factors. By consolidating this information, preventive maintenance and system improvements become substantially more manageable, resulting in significant expense reductions and enhanced operational performance throughout the facility.

The integration framework must be durable and dependable, maintaining information precision and reducing delays. This setup permits rapid reactions to urgent circumstances and allows automated control systems to better distribute resources while maintaining consistent environmental conditions for building users.

Real-Time Monitoring and Alerting

Continuous tracking of essential performance metrics is vital for successful intelligent building administration. This functionality enables instant detection of possible concerns, such as device failures or abnormal energy usage trends, allowing quick corrective actions that prevent more serious complications. The capacity to obtain immediate warnings and notifications proves invaluable, permitting preventive measures that reduce service interruptions.

Connection with cloud-based systems facilitates remote supervision and control, which proves particularly useful for facility operators who may work off-site. This distant monitoring ability enables rapid reaction to developing situations, improving the general functionality and dependability of the building infrastructure.

Improved Energy Efficiency through Automation

Smart building control solutions utilize IoT hardware and cloud services to implement energy-saving operations automatically. This encompasses modifying illumination intensity according to room occupancy, fine-tuning climate control systems for ideal comfort with minimal energy expenditure, and establishing intelligent timetables for appliances and machinery. These automated functions make a substantial contribution to decreasing power usage and reducing running expenses.

Optimized Maintenance Schedules

By evaluating information from numerous sensors and connected devices, smart building management platforms can anticipate possible service requirements. This enables preventive maintenance planning, lowering the probability of sudden equipment breakdowns and minimizing operational interruptions. These predictive maintenance features directly result in considerable financial savings and enhanced system dependability.

Enhanced Security and Access Control

Incorporating IoT technology for entry management improves safety measures and simplifies facility administration. Automated entry systems, monitored access areas, and live observation of visitor movements establish a more protected atmosphere for both regular occupants and guests. The combination of these technologies reinforces security measures and helps create a safer building environment.

Improved Occupant Comfort and Experience

Intelligent building control systems can customize environmental parameters to individual needs, improving user comfort and overall satisfaction. Personalized climate adjustments, customizable illumination settings, and enhanced air quality monitoring positively influence the health and work output of building users. The resulting comfort improvements directly contribute to a more effective and enjoyable workplace atmosphere.

Scalability and Adaptability for Future Growth

Successful intelligent building management platforms must demonstrate flexibility and expandability to meet evolving requirements and future expansion. The capability to incorporate additional devices and features, along with modifying current configurations, proves essential for preserving system performance and usefulness. The sturdy system design allows for effortless incorporation of upcoming technologies and changing operational demands.

Read more about Smart Building Management Systems: Next Gen Features

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing