Sustainable Real Estate: The Business Case for Eco Friendly Development and Operations

Streamlined Processes for Efficiency

Implementing lean methodologies and process improvements can significantly reduce operational costs. By identifying and eliminating unnecessary steps and redundancies within workflows, businesses can optimize resource allocation and free up capital for growth initiatives. This streamlining not only reduces labor costs but also minimizes material waste and improves overall productivity. A well-defined and streamlined process ensures that resources are used effectively, minimizing errors and maximizing output.

Analyzing current processes and identifying bottlenecks is crucial for implementing effective changes. By understanding where inefficiencies lie, businesses can implement targeted solutions to improve workflow and achieve substantial cost savings. This detailed analysis often reveals hidden opportunities for automation, leading to further cost reductions.

Optimized Inventory Management

Effective inventory management plays a vital role in lowering operating costs. By implementing systems that accurately track inventory levels and predict demand, businesses can avoid overstocking and the associated costs of storage, obsolescence, and potential write-offs. Maintaining optimal stock levels ensures that materials are readily available when needed, minimizing disruptions to production and reducing the risk of stockouts.

Implementing just-in-time inventory systems can significantly reduce the need for large storage spaces and associated costs. These systems allow businesses to receive materials only when they are needed for production, minimizing holding costs and reducing the risk of outdated or obsolete inventory.

Technology Integration for Automation

Integrating relevant technology solutions, such as automated systems and software applications, can significantly reduce operational costs. Automating repetitive tasks can free up employees for more strategic and valuable work. This not only reduces labor costs but also improves accuracy and efficiency, leading to a greater return on investment.

Furthermore, technology can improve data collection and analysis, providing valuable insights into operational trends and potential areas for cost savings. Data-driven decision-making can lead to more efficient resource allocation and better management of overall operational costs.

Negotiated Supply Chain Partnerships

Building strong relationships with suppliers through negotiation and strategic partnerships can often lead to significant cost reductions throughout the supply chain. Negotiating favorable terms and conditions with key suppliers can result in substantial discounts on materials and services, directly impacting operating costs. Moreover, reliable and trustworthy suppliers can contribute to reduced lead times, minimizing delays and associated costs.

Reduced Energy Consumption

Implementing energy-efficient practices and technologies can lead to substantial cost savings. By optimizing energy use in various operational processes, businesses can reduce their energy bills and improve their environmental footprint. Switching to energy-efficient equipment and implementing smart energy management systems can lead to significant long-term savings.

This includes measures like reducing unnecessary lighting, optimizing HVAC systems, and adopting renewable energy sources where possible. These strategies can contribute significantly to reducing operating costs while promoting sustainability.

Employee Training and Development

Investing in employee training and development programs can ultimately reduce operating costs in the long run. A well-trained workforce is more productive, efficient, and less prone to errors. This translates to lower labor costs, reduced material waste, and improved quality control. This can enhance employee skillsets, leading to greater efficiency and reduced errors, further contributing to cost savings.

By creating a skilled and engaged workforce, businesses can foster a culture of continuous improvement and innovation, leading to long-term cost savings and enhanced operational performance.

Waste Reduction and Recycling Initiatives

Implementing waste reduction and recycling programs can significantly contribute to lower operating costs. By minimizing waste generation through efficient processes and proper waste management, businesses can reduce disposal costs and achieve environmental sustainability. Recycling materials can also lead to cost savings by reducing the need for purchasing new materials.

These initiatives not only save money but also enhance the company's environmental image. This can attract environmentally conscious consumers and investors, further contributing to the overall success of the business.

CRISPR-Cas9 gene editing technology has emerged as a revolutionary tool with immense potential to manipulate the human immune system. Its precise targeting capabilities allow scientists to modify immune cells, such as T cells, to enhance their ability to recognize and destroy cancerous cells or infected cells. This precise editing offers a pathway to potentially create more effective immunotherapies.

Read more about Sustainable Real Estate: The Business Case for Eco Friendly Development and Operations

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

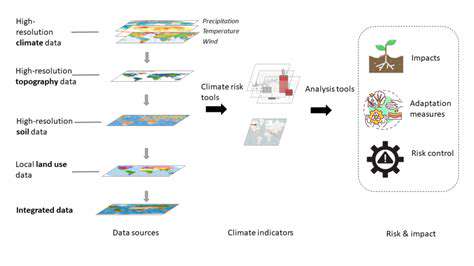

- Understanding Climate Risk in Real Estate Financing