Zero Waste Construction Sites: Economic Advantages

Reduced Landfill Disposal Costs: A Significant Savings

Implementing zero-waste strategies on construction sites can lead to substantial reductions in landfill disposal costs. By diverting waste from landfills, projects can avoid the substantial financial burden associated with disposal fees, transportation, and potential environmental remediation costs. This significant savings translates directly into a more profitable and sustainable project, showcasing the economic benefits of adopting zero-waste practices.

The cost savings from reduced landfill disposal extend beyond the initial project budget. Long-term cost savings are realized by avoiding future liabilities related to landfill management and potential environmental cleanup. This proactive approach to waste management ensures that construction projects are not only financially sound but also environmentally responsible in the long run.

Waste Diversion Programs: Key to Cost Reduction

Effective waste diversion programs are central to achieving reduced landfill disposal costs. These programs systematically identify and separate recyclable and reusable materials from construction and demolition debris. This careful sorting process ensures that valuable resources are recovered for reuse, minimizing the amount of waste destined for landfills.

Material Recovery and Reuse: Maximizing Value

Implementing material recovery and reuse programs is a crucial component of zero-waste construction. By focusing on the reuse of construction materials, projects can minimize waste generation and simultaneously recover valuable resources. This process not only reduces landfill disposal costs but also incorporates a circular economy approach, promoting resource efficiency and sustainability.

The careful planning and execution of material recovery and reuse programs can yield substantial cost savings. By identifying opportunities to reuse materials, businesses can reduce the demand for virgin materials, thus lowering procurement costs and minimizing waste generation throughout the entire construction process. This approach also helps to foster a more sustainable and resourceful approach to construction.

Pre-Planning and Design for Waste Reduction

Proactive pre-planning and design strategies are essential for achieving significant waste reductions and, consequently, lower landfill disposal costs. By incorporating waste minimization principles into the project's initial design phase, projects can optimize material selection, reduce excess material, and incorporate innovative approaches for efficient construction practices.

A comprehensive understanding of the project's specific materials and waste generation patterns allows for the development of tailored strategies to minimize waste throughout the project lifecycle. This crucial pre-planning minimizes the risk of waste generation and maximizes opportunities for material reuse, leading to substantial cost savings associated with landfill disposal.

Effective Communication and Training: Essential for Success

Clear communication and comprehensive training programs are critical for the successful implementation of zero-waste strategies. Effective communication ensures that all project stakeholders, including workers, subcontractors, and suppliers, understand the importance of waste reduction and the specific procedures to follow. This unified approach to waste management ensures consistency and maximizes the project's potential for waste reduction.

Proper training equips project personnel with the knowledge and skills to effectively separate, sort, and manage construction and demolition debris. This leads to a more organized and efficient waste management process, reducing the likelihood of errors and maximizing the recovery of valuable materials. This focus on training demonstrates a commitment to sustainability and promotes a culture of waste reduction on the construction site.

Monitoring and Evaluation: Continuous Improvement

Regular monitoring and evaluation of waste diversion efforts are crucial for ensuring continuous improvement in waste reduction and cost savings. By tracking the amount of waste diverted from landfills, projects can identify areas for improvement and refine their strategies accordingly. This data-driven approach allows for the optimization of waste management practices, maximizing resource recovery and minimizing landfill disposal costs.

Sustainable Practices: Long-Term Benefits

Implementing zero-waste practices on construction sites is not just about reducing landfill disposal costs; it's about embracing sustainable practices that yield long-term benefits. By adopting a circular economy approach, construction projects can significantly reduce their environmental footprint and contribute to a more sustainable future. This approach promotes resource efficiency, reduces reliance on virgin materials, and fosters a mindful approach to waste management that benefits both the project and the environment.

Optimized Material Procurement and Resource Efficiency

Streamlining Procurement Processes

Effective material procurement is crucial for achieving zero waste on a construction site. A well-defined procurement process, incorporating detailed specifications, clear communication channels, and pre-approved vendor lists, reduces the likelihood of ordering incorrect or excessive materials. This meticulous approach not only minimizes waste from unused materials but also fosters a culture of conscious consumption, a key element of zero-waste construction.

Implementing a robust system for tracking material deliveries and quantities received is equally important. This real-time visibility allows for accurate inventory management, reducing the risk of overstocking and subsequent waste. Furthermore, pre-planning and accurate material take-offs, based on precise project designs and specifications, will significantly lessen the need for on-site material adjustments, further minimizing waste.

Prioritizing Sustainable Materials

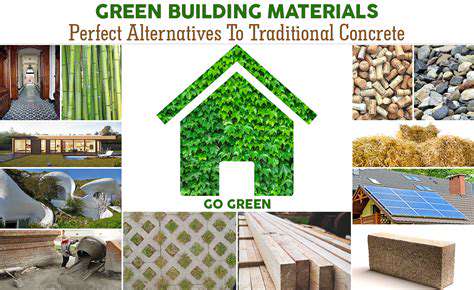

A zero-waste construction site prioritizes the use of sustainable, recycled, and locally sourced materials. This commitment encompasses not just the selection of materials, but also the consideration of their entire lifecycle. From sourcing to disposal, sustainable materials contribute to a smaller environmental footprint and reduce the reliance on virgin resources.

This includes exploring options like recycled aggregates, reclaimed wood, and pre-fabricated components. Choosing products with a lower embodied energy and a reduced carbon footprint is fundamental to achieving zero-waste goals. This conscientious approach extends beyond the immediate project and contributes to the broader sustainability movement.

Implementing Lean Construction Principles

Integrating lean construction principles into the project management process will optimize material usage. These principles emphasize waste elimination at all stages, from the initial planning phase to the final completion. This holistic approach ensures that every step of the project contributes to minimizing material waste and maximizing efficiency.

By focusing on minimizing material handling, reducing lead times, and improving communication between all stakeholders, lean construction enhances the efficiency of the entire project. This also helps prevent waste from errors and delays, further supporting the goal of a zero-waste site.

Accurate Material Take-offs and Planning

Precise material take-offs, based on detailed blueprints and specifications, are fundamental to optimized material procurement. Thorough planning reduces the risk of ordering excessive materials, preventing unnecessary waste and costs. By ensuring the accurate calculation of required quantities, the project team can avoid ordering more materials than needed, minimizing the risk of material surplus.

Regular reviews of the material take-offs throughout the project lifecycle are vital for adjusting quantities based on progress and potential deviations. This adaptability helps to manage any unexpected changes and minimizes the possibility of waste from excess materials.

Waste Reduction Strategies on Site

Implementing effective waste reduction strategies on site is crucial for minimizing material waste. This includes establishing clear procedures for segregating and recycling construction debris. Dedicated recycling areas and personnel are essential for efficient waste management.

Active communication with waste management services is needed to ensure proper disposal methods for different material types. This careful attention to detail and organized waste handling further reduces the environmental impact of the project and promotes a zero-waste environment on the construction site.

Monitoring and Evaluation for Continuous Improvement

Regular monitoring and evaluation of material procurement and resource use are critical for achieving and maintaining zero-waste construction practices. Tracking material usage, identifying areas for improvement, and adjusting strategies accordingly are essential elements for continuous improvement. This ongoing process ensures that the project stays on track with its zero-waste goals.

Data analysis from these monitoring efforts provides valuable insights into material waste patterns. This information allows for the identification of potential issues and the implementation of corrective actions, fostering a culture of continuous improvement and promoting the long-term sustainability of the project and the construction site.

Modern classrooms have witnessed a transformation with the introduction of interactive whiteboards (IWBs), which serve as dynamic platforms for collaborative learning. These innovative tools create shared digital spaces where students can brainstorm ideas, take notes collectively, and solve problems together, shifting education from passive absorption to active participation. The tactile nature of these boards encourages learners to interact directly with educational content.

Enhanced Reputation and Attracting Sustainable Investors

Strengthening Brand Image

A commitment to zero-waste construction significantly enhances a company's brand image, positioning it as environmentally conscious and forward-thinking. This resonates with a growing segment of consumers and investors who prioritize sustainability. Companies demonstrating a dedication to minimizing waste materials and maximizing resource efficiency are perceived as responsible corporate citizens, boosting public trust and attracting a positive reputation within the industry and beyond.

This positive perception translates into increased customer loyalty and potential for attracting partnerships with environmentally conscious businesses. Moreover, a strong brand image built on sustainability can create a competitive advantage, as consumers increasingly seek out products and services aligned with their values.

Attracting Socially Conscious Investors

Sustainable investors are increasingly seeking out companies with robust environmental, social, and governance (ESG) practices. Zero-waste construction demonstrably aligns with these values, signaling a company's commitment to long-term sustainability and responsible resource management. This commitment is not just a short-term marketing strategy, but a core principle embedded within the company's operations, making it attractive to investors who understand and value environmental stewardship.

By showcasing a strong commitment to zero-waste practices, companies can attract a new pool of investors who are actively seeking out companies with a demonstrable track record of sustainable practices. This, in turn, can lead to a more stable and secure funding source, fostering long-term growth and resilience.

Improved Operational Efficiency

Implementing zero-waste construction strategies often leads to improved operational efficiency. Careful planning and material management minimize waste and rework, leading to reduced costs associated with disposal and material sourcing. The focus on reducing waste stream complexity streamlines operations, resulting in more efficient use of labor and resources throughout the construction process. This improved efficiency translates to tangible cost savings and enhanced profitability over the long term.

Furthermore, a streamlined workflow and reduced waste can lead to shorter project timelines. This is particularly important in today's competitive construction market, where timely project completion is essential for maintaining a strong reputation and securing future contracts.

Long-Term Financial Viability

Zero-waste construction practices contribute significantly to long-term financial viability. By reducing waste and maximizing resource utilization, companies can minimize material costs and disposal fees. This translates directly into cost savings, enhancing profitability and strengthening the financial health of the company in the long run. Sustainable practices that reduce waste ultimately reduce the overall environmental footprint, which can also lead to potential tax incentives or other forms of government support for environmentally responsible companies.

Enhanced Stakeholder Relationships

A commitment to zero-waste construction fosters strong relationships with various stakeholders, including local communities, regulatory bodies, and suppliers. By demonstrating a commitment to environmental responsibility, companies build trust and credibility with these groups. This fosters positive relationships that can lead to increased cooperation, streamlined permitting processes, and enhanced community support. Sustainable practices create a culture of collaboration and mutual respect throughout the project lifecycle, which can be a key differentiator in securing future projects and partnerships.

Stronger relationships with stakeholders also translate into a more positive public perception, promoting goodwill and positive brand recognition. This further strengthens the company's position in the market and enhances its ability to secure future projects and contracts.

Read more about Zero Waste Construction Sites: Economic Advantages

Hot Recommendations

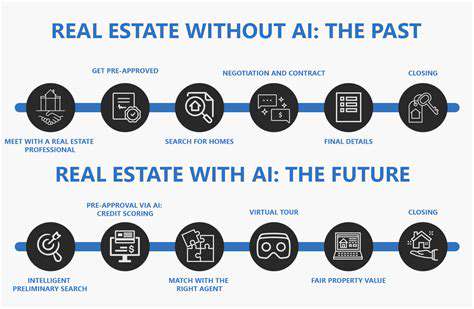

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

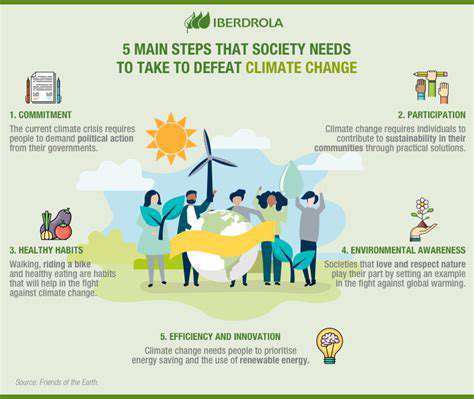

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

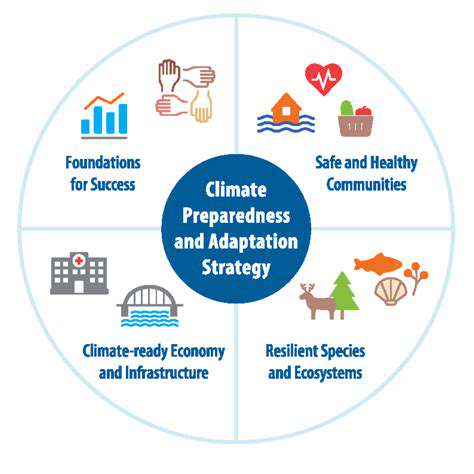

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing