Sustainable Construction Materials: Embodied Carbon

Effective Approaches for Minimizing Carbon Impact in Current Structures

Enhancing Structural Thermal Efficiency

One fundamental method for decreasing material-based carbon emissions in existing structures focuses on improving the building's thermal barrier. This involves comprehensive upgrades including advanced thermal barriers, comprehensive draft proofing, and installation of modern fenestration solutions. Strengthening the thermal efficiency of the enclosure directly decreases energy requirements for climate control systems, consequently reducing ongoing carbon emissions. Modernization using cutting-edge materials, like phase-change insulation or triple-pane glazing, can dramatically improve thermal retention, resulting in considerable energy conservation throughout the building's service life. Additionally, eliminating air infiltration reduces dependence on auxiliary climate systems, leading to decreased total carbon emissions.

Applying these methods not only lowers the building's operational energy needs but also reduces consumption of carbon-intensive materials during renovation. Meticulous evaluation of each material's carbon impact is crucial to guarantee the complete project aligns with emission reduction goals. By selecting durable, high-efficiency materials with excellent recyclability, construction teams can substantially lessen the environmental consequences of the renovation process.

Modernizing Climate Control Infrastructure

Heating, ventilation, and air conditioning systems represent major factors in a building's energy profile and associated material carbon. Transitioning to contemporary, energy-conscious HVAC technologies can produce dramatic efficiency gains. This typically means adopting systems with superior energy performance metrics (such as elevated SEER ratings for cooling units). Incorporating intelligent monitoring systems and automated building controls can further refine energy utilization by dynamically adjusting environmental systems based on occupancy patterns and current conditions. These adaptive systems can progressively optimize their operation according to building requirements, achieving meaningful reductions in unnecessary energy expenditure.

Beyond equipment replacement, exploring renewable energy integration for HVAC operations presents additional opportunities. Options include photovoltaic array installations or ground-source thermal exchange systems to decrease dependence on conventional electricity grids, which frequently carry substantial carbon burdens. By incorporating sustainable power solutions into climate system design, structures can achieve comprehensive carbon reduction across both material and operational phases.

Selecting Eco-Conscious Materials for Renovations

Material selection represents a critical factor in minimizing carbon impact during building upgrades. Emphasize materials with minimal carbon profiles, including reprocessed components, regionally available resources, or products made using clean energy. Using recycled building elements decreases demand for new resource extraction, thereby reducing environmental damage from mining and processing operations. Sustainable building products typically feature reduced carbon footprints and extended durability, yielding lower environmental consequences over extended periods.

Material considerations should encompass interior surface treatments and fixtures as well. Choosing carbon-conscious finishes like salvaged timber or rapidly renewable bamboo can substantially decrease a project's ecological impact. Additionally, selecting paints and adhesives with minimal volatile organic compounds reduces emission of harmful substances during and following construction activities.

Comprehensive Material Reclamation Approaches

Sophisticated material reclamation and deconstruction methods play an essential role in limiting environmental effects of building renovations. Establishing thorough material separation protocols ensures proper recycling or disposal, preventing landfill accumulation. This decreases greenhouse gas production from waste breakdown while facilitating reuse of valuable resources. Recycling and repurposing initiatives during demolition and reconstruction can meaningfully reduce overall project impacts, lowering the material carbon burden of renovated spaces.

Creating demolition plans that emphasize material recovery is fundamental. Identify and preserve reusable structural elements like timber, steel, and concrete for subsequent applications, thereby reducing demand for virgin materials and decreasing carbon emissions. This methodology not only reduces material carbon but also supports resource circularity by optimizing use of existing materials.

Advancements in Sustainable Building Material Science

Material Carbon: An Increasing Priority in Construction

The consideration of material carbon - the total greenhouse gases emitted across a building component's entire lifecycle - has emerged as a crucial element in sustainable development. From initial resource acquisition through manufacturing to final decommissioning, each phase contributes to cumulative environmental impact. Recognizing and addressing these emissions is essential for establishing genuinely sustainable construction methodologies and reducing our ecological footprint.

This heightened awareness highlights the critical need for creative solutions that decrease material carbon in construction products and techniques. Transitioning toward environmentally responsible design decisions is imperative for creating built environments that benefit rather than burden our planet.

Cutting-Edge Material Innovations

Among the most hopeful directions for material carbon reduction is the creation and implementation of advanced building products. Scientific investigations are examining sustainable substitutes for conventional materials, including novel concrete formulations incorporating industrial byproducts and innovative composites with reduced carbon impacts. Significant progress is being made with organic materials such as fast-growing grasses and fungal-derived substances, presenting opportunities for substantial carbon reduction in the building sector.

Architectural Planning for Carbon Efficiency

Design methodology significantly influences material carbon reduction. Thoughtful material specification, efficient spatial organization, and strategic implementation of prefabricated elements can dramatically lower a project's environmental consequences. Design professionals are progressively integrating full lifecycle analyses into their workflows, enabling thorough evaluation of a structure's environmental effects from creation to deconstruction.

Moreover, emphasizing component-based construction and off-site fabrication can meaningfully reduce transportation-related emissions from material distribution while minimizing construction waste. These design considerations are becoming increasingly vital for meeting sustainability objectives in the built environment.

Quantifying Environmental Impact

Precise carbon measurement and documentation form the foundation for understanding material carbon in construction projects. Developing reliable techniques to assess the carbon consequences of various materials and building processes is essential for informed decision-making and establishing practical reduction goals. This requires creating uniform assessment protocols and industry-wide cooperation to disseminate optimal carbon accounting practices.

Regulatory Initiatives and Standards

Government initiatives and building regulations can significantly accelerate adoption of low-carbon construction methods. Encouraging sustainable material use through incentives, establishing carbon benchmarks for structures, and implementing stricter controls on high-emission products can promote environmentally conscious practices. International coordination and information exchange are critical for establishing worldwide standards in sustainable construction.

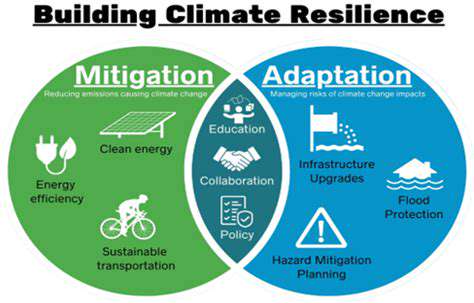

Industry Cooperation and Knowledge Sharing

The shift toward sustainable construction demands collaboration among diverse stakeholders including designers, builders, material producers, and regulators. Specialized training programs are necessary to provide professionals with expertise required for creating and maintaining low-carbon buildings. Increasing public understanding of material carbon concepts can help establish sustainability as a fundamental principle in construction practices.

Read more about Sustainable Construction Materials: Embodied Carbon

Hot Recommendations

- AI in Property Marketing: Virtual Tours and VR

- Water Management Solutions for Sustainable Real Estate

- IoT Solutions for Smart Building Energy Management

- Sustainable Real Estate: Building a Greener Tomorrow

- Sustainable Real Estate: From Concept to Community

- AI Driven Due Diligence for Large Scale Developments

- Real Estate Sector and Global Climate Agreements

- Smart Buildings: The Key to Smarter Property Management

- Zero Waste Buildings: A Sustainable Real Estate Goal

- Understanding Climate Risk in Real Estate Financing